Impeller Trimming and Its Impact on Pump Performance

In industrial plants, centrifugal pumps are critical for fluid transfer in processes such as water supply, chemical injection, and slurry transportation. The impeller, as the core energy-conversion component, directly determines the pump’s flow rate, head, and efficiency. When a pump’s operating parameters (flow, head) do not match the on-site requirements, impeller trimming—machining the impeller to reduce its outer diameter—emerges as a cost-effective adjustment method. This article, from a plant operation perspective, systematically explains the technical principles, performance impacts, and practical considerations of impeller trimming to guide rational application in production.

1. Why Do Plants Need Impeller Trimming?

During plant design or equipment replacement, pumps are often selected based on maximum process requirements, leading to mismatches under actual operating conditions. Common scenarios requiring impeller trimming include:

·Overcapacity: The pump’s rated flow/head exceeds the actual demand, causing energy waste (e.g., a 100 kW motor operating at only 60% load) or needing to throttle valves to reduce flow, which increases pipeline resistance and energy consumption.

·Process Adjustments: Changes in production load (e.g., reduced output of a chemical reactor) require lower flow rates, but replacing the entire pump is costly and time-consuming.

·System Matching: Newly added pipelines or equipment increase system resistance, requiring the pump to operate at a lower head to avoid overpressure.

Impeller trimming offers a flexible solution: by reducing the impeller diameter, the pump’s performance curve shifts downward to match the actual operating point, improving energy efficiency and reducing wear caused by throttling.

2. Technical Principles of Impeller Trimming

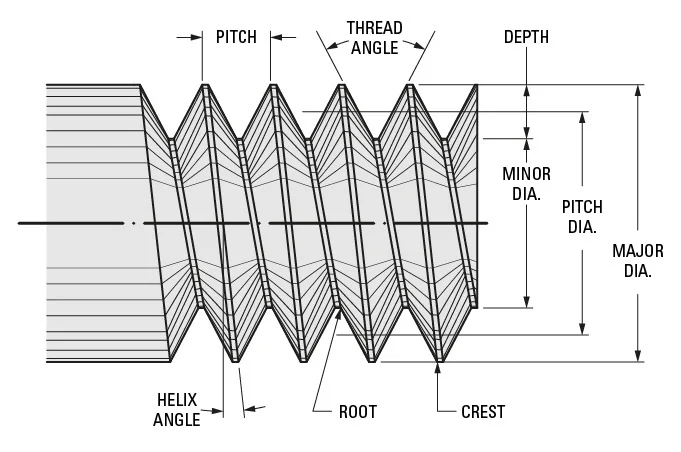

The impeller transfers mechanical energy to the fluid through centrifugal force generated by rotation. The outer diameter (D) of the impeller directly affects the fluid’s tangential velocity at the outlet (u₂ = πDn/60, where n is rotational speed), which in turn determines the pump’s head (H ∝ u₂²) and flow rate (Q ∝ u₂ × impeller outlet area).

Trimming the impeller reduces its outer diameter, thereby decreasing u₂ and altering the performance parameters. These changes follow the affinity laws for constant rotational speed:

·Flow Rate (Q): Proportional to the impeller diameter.

Q₂ = Q₁ × (D₂/D₁)

Example: Trimming a 300 mm diameter impeller to 270 mm (10% reduction) reduces flow rate by 10%.

·Head (H): Proportional to the square of the impeller diameter.

H₂ = H₁ × (D₂/D₁)²

Example: A 10% diameter reduction leads to a 19% head decrease (1 - 0.9² = 0.19).

·Shaft Power (P): Proportional to the cube of the impeller diameter.

P₂ = P₁ × (D₂/D₁)³

Example: A 10% diameter reduction reduces power consumption by 27% (1 - 0.9³ = 0.27), significantly saving energy.

These laws are valid for small trimming ranges (typically ≤10% of the original diameter). For larger trims, deviations occur due to changes in impeller hydraulic efficiency.

3. Impact of Impeller Trimming on Pump Performance

Plant operators must understand how trimming affects key performance indicators to avoid operational risks:

3.1 Efficiency Changes

·Small Trimming (≤10%): Efficiency remains nearly unchanged (±2%), as the impeller’s vane shape and flow channel structure are minimally altered.

·Large Trimming (>10%): Efficiency decreases significantly, especially for high-specific-speed pumps (Ns > 100 SI). For example, trimming a 300 mm impeller to 240 mm (20% reduction) may reduce efficiency by 5–8% due to increased hydraulic loss at the vane outlet.

Plant Implication: For energy-intensive pumps (e.g., 200 kW+), large trims may offset energy savings from reduced power consumption, requiring a cost-benefit analysis.

3.2 Net Positive Suction Head Required (NPSHR)

NPSHR is the minimum inlet pressure required to prevent cavitation. Its relationship with impeller trimming depends on the trimming range and pump specific speed:

·Trimming ≤10%: NPSHR remains stable for low-specific-speed pumps (Ns < 30 SI), as the inlet flow field is not significantly disturbed.

·Trimming >10%: For high-specific-speed pumps (Ns > 60 SI), NPSHR increases by 5–15% because the reduced impeller diameter causes flow recirculation between the outlet and inlet, disrupting the inlet flow pattern and increasing local pressure loss.

Plant Implication: After trimming, if the system’s available NPSH (NPSHA) is close to the original NPSHR, cavitation risk rises. Operators should recheck NPSHA (NPSHA = P inlet + P atmospheric - P vapor) and ensure NPSHA ≥ 1.2 × NPSHR.

3.3 Operating Stability

·Flow Recirculation: Excessive trimming (e.g., >15% for low-specific-speed pumps) may cause flow separation at the vane inlet, leading to unstable operation, increased vibration (vibration velocity >4.5 mm/s), and noise.

·Motor Load: Trimming reduces power consumption, which is beneficial for avoiding motor overload. However, if the trimmed pump operates at a flow rate higher than the new rated flow (e.g., due to pipeline pressure drop reduction), the motor may still be overloaded.

Plant Implication: After trimming, monitor motor current to ensure it does not exceed the rated value, especially during startup.

4. Practical Guidelines for Plant Impeller Trimming

To ensure safe and effective trimming, plants should follow these steps:

4.1 Determine the Optimal Trimming Range

·Calculate the Target Diameter: Based on the required operating point (Q₂, H₂), use the affinity laws to derive D₂ = D₁ × √(H₂/H₁) or D₂ = D₁ × (Q₂/Q₁).

·Limit Trimming to ≤15%: Exceeding this range risks severe efficiency loss and instability. For larger adjustments, consider replacing the impeller with a smaller standard size.

4.2 Professional Machining Requirements

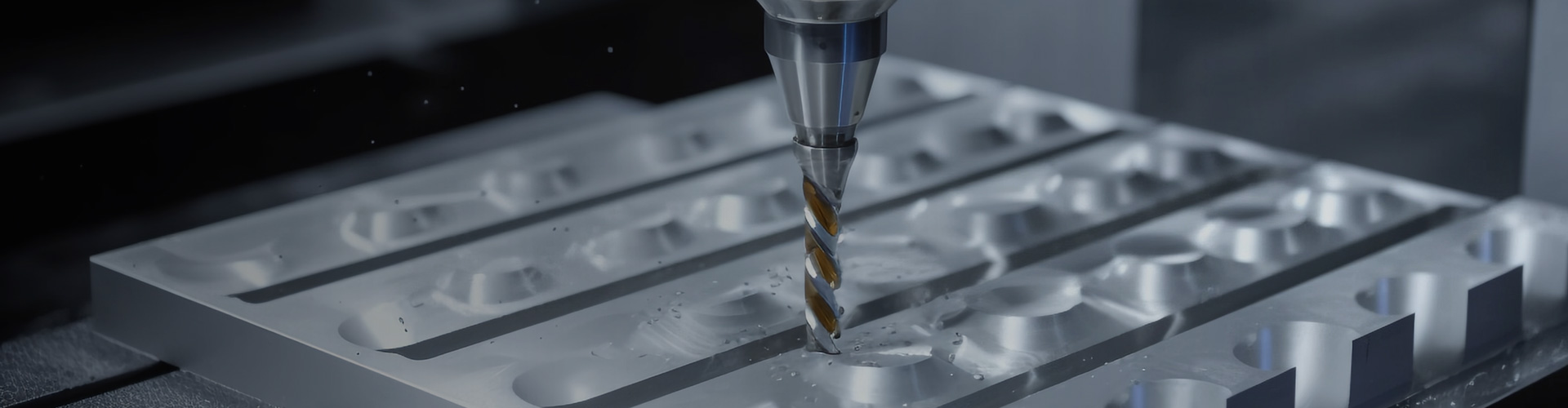

·Precision Machining: The trimmed impeller must maintain dynamic balance (residual unbalance ≤ G6.3 as per ISO 1940) to avoid vibration. The outer diameter tolerance should be controlled within ±0.1 mm, and the blade tip must be smooth (Ra ≤ 3.2 μm) to reduce hydraulic loss.

·Material Considerations: For high-chrome cast iron impellers (slurry pumps), use diamond grinding tools to prevent edge chipping; for stainless steel impellers (chemical pumps), ensure no burrs to avoid corrosion initiation.

4.3 Post-Trimming Testing

·Performance Verification: Conduct a pump test to measure actual flow, head, and efficiency under operating conditions, ensuring they match the target values.

·Cavitation Check: Monitor inlet pressure and vibration during operation. If cavitation occurs (e.g., crackling noise, sharp vibration increase), adjust the system (e.g., increase inlet pressure, clean filters) promptly.

·Long-Term Monitoring: Track bearing temperature, vibration, and motor current for 1–2 weeks post-trimming to confirm stable operation.

5. Alternatives to Impeller Trimming

In some cases, trimming may not be the best option. Plants can be considered:

·Variable Frequency Drives (VFD): Adjusting rotational speed to change performance, which is more energy-efficient than trimming for varying loads (e.g., 30–100% flow).

·Replacing with a Smaller Impeller: Standard impellers from manufacturers ensure better hydraulic performance than trimmed ones, suitable for long-term fixed operating points.

·Throttling Valves: Simple but energy-inefficient, only suitable for short-term, low-power pumps (≤10 kW).

Conclusion

Impeller trimming is a practical method for adjusting pump performance in plant operations, effectively resolving mismatches between pump capacity and process requirements. However, it requires strict control of the trimming range (<15%), professional machining, and post-trim testing to avoid efficiency loss and operational risks. For plants, the key is to balance short-term adjustment needs with long-term energy efficiency—choosing trimming for fixed low-load conditions, VFDs for variable loads, and ensuring all adjustments align with the pump’s design limits to maintain reliability and reduce maintenance costs.