Key Considerations for Switching to Non-OEM Pump Parts

In industrial maintenance, the choice between Original Equipment Manufacturer (OEM) parts and non-OEM (replicated) parts has long been a critical decision. While non-OEM parts often attract attention with lower upfront costs, their long-term impact on equipment reliability, performance, and lifecycle costs requires in-depth technical evaluation. This article systematically analyzes the risks and potential benefits of non-OEM parts from an engineering perspective, providing a decision-making framework for maintenance teams.

1. Core Differences Between OEM and Non-OEM Parts

To understand the trade-offs, it is first necessary to clarify the essential differences in their design and production:

·OEM Parts: Produced by the pump manufacturer or authorized suppliers, they strictly follow the original design drawings, material specifications, and quality control processes. Key features include:

·Design Consistency: Fully compatible with the original equipment, with dimensional tolerances (e.g., impeller outer diameter, bearing clearance) controlled within ±0.01 mm to ensure optimal fit.

·Material Compliance: Use of certified materials (e.g., 316 stainless steel for corrosion resistance, high-chrome cast iron for wear resistance) with traceable metallurgical properties (e.g., hardness, tensile strength).

·Performance Validation: Undergo factory testing (e.g., impeller dynamic balance, seal leakage rate) to match the pump’s rated parameters (flow, head, efficiency).

·Non-OEM Parts: Produced by third-party manufacturers through reverse engineering or imitation. Their quality varies significantly:

·Design Dependence: Rely on copying existing parts (rather than original drawings), which may lead to dimensional deviations if the prototype is worn or damaged.

·Material Substitution: May use cheaper alternative materials (e.g., 201 stainless steel instead of 316, ordinary rubber instead of EPDM) to reduce costs, sacrificing corrosion resistance or temperature resistance.

·Limited Testing: Rarely undergo full performance validation; focus is often on basic functionality rather than long-term reliability.

2. Technical Risks of Non-OEM Parts

Switching to non-OEM parts without evaluation may introduce hidden risks that affect pump operation. The following are key risk points:

2.1 Warranty and After-Sales Risks

Most pump manufacturers explicitly state in their warranty terms that using non-OEM parts will void the original warranty. This means any failures caused by part incompatibility (e.g., impeller wear leading to shaft damage) will not be covered by the manufacturer, resulting in additional repair costs. For new pumps (within 1–2 years of purchase), this risk is particularly significant—OEM parts should be prioritized during the warranty period to leverage free repair services.

2.2 Performance Deviation

Critical components such as impellers, casings, and mechanical seals directly affect pump efficiency and stability. Non-OEM parts often struggle to replicate OEM performance:

·Impellers: The vane shape, curvature, and outlet angle are key to hydraulic efficiency. Non-OEM impellers copied from worn prototypes may have uneven vane thickness or incorrect angles, reducing efficiency by 5–15% and increasing energy consumption.

·Seals: Mechanical seal faces require precise flatness (≤0.001 mm) and material matching (e.g., silicon carbide vs. carbon). Non-OEM seals may have rough surfaces or mismatched materials, leading to leakage rates exceeding 10 mL/h (vs. <5 mL/h for OEM) and increasing the risk of fluid loss or environmental contamination.

·Bearings: Clearance and material hardness directly affect service life. Non-OEM bearings with excessive clearance (e.g., 0.1 mm instead of the standard 0.05 mm) may cause shaft vibration, accelerating wear of the impeller and casing.

2.3 Dimensional and Fit Issues

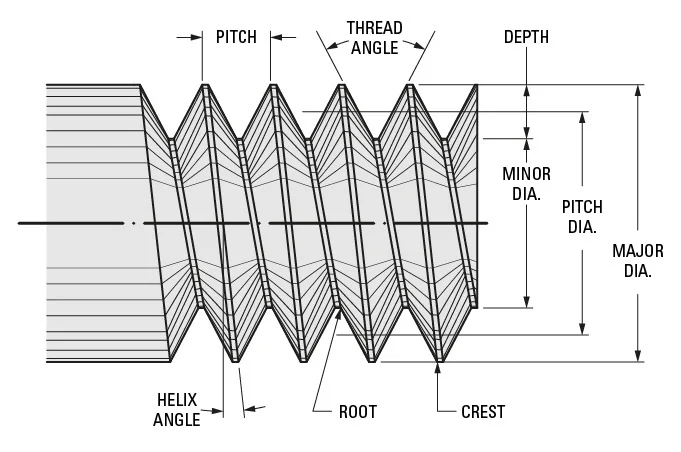

Pump components rely on precise fits to function (e.g., the gap between the impeller and casing, the interference fit between the shaft and bearing). Non-OEM parts often have dimensional deviations due to:

·Lack of Original Drawings: Without access to the manufacturer’s design data, third parties can only measure existing parts. If the measured part is worn (e.g., a shaft with 0.2 mm wear), the copied part will inherit this error, leading to excessive clearance or jamming.

·Simplified Processing: To reduce costs, non-OEM manufacturers may omit fine machining steps (e.g., impeller dynamic balancing, shaft surface grinding), resulting in unbalanced rotation and increased vibration (vibration velocity >4.5 mm/s, exceeding the ISO 10816 standard).

2.4 Material Quality Risks

Material properties directly determine component durability, especially in harsh environments (corrosive, high-temperature, or abrasive media):

·Corrosion Resistance: Non-OEM parts may use uncertified stainless steel (e.g., 304 instead of 316) in chemical pumps, leading to pitting corrosion in chloride environments and reducing service life from 5 years to 1–2 years.

·Wear Resistance: High-chrome cast iron impellers (Cr content ≥27%) used in slurry pumps require strict control of carbide distribution. Non-OEM versions with lower Cr content (e.g., 15%) will wear 3–5 times faster, increasing replacement frequency.

·Temperature Resistance: Sealing materials (e.g., O-rings) in high-temperature pumps must withstand 120–200°C. Non-OEM parts using ordinary nitrile rubber (maximum 80°C) may harden or crack, causing sudden leaks.

3. When Can Non-OEM Parts Be Considered?

While risks exist, non-OEM parts are not entirely unfeasible. Under the following conditions, they can be used as a cost-effective alternative:

·Out of Warranty Period: For pumps beyond the warranty period (e.g., 5+ years old), the impact of voiding the warranty is negligible, and non-OEM parts can reduce maintenance costs.

·Non-Critical Components: For low-risk parts with simple structures (e.g., gaskets, O-rings, pressure gauge adapters), qualified non-OEM products (meeting ISO 9001 or FDA standards) can be used—their failure is unlikely to cause cascading damage to the pump.

·Reputable Suppliers: Choose non-OEM manufacturers with reverse engineering capabilities and quality systems. Verify that they:

·Use 3D scanning or coordinate measuring machines (CMM) for dimensional verification (tolerance ≤±0.02 mm).

·Provide material certification (e.g., mill test reports for metals, FDA certificates for rubber).

·Offer performance testing data (e.g., impeller efficiency curves, seal pressure resistance).

·Pilot Testing: For critical components (e.g., impellers), conduct a small-scale trial: install non-OEM parts on a backup pump, monitor key indicators (efficiency, vibration, temperature) for 3–6 months, and compare with OEM parts before full-scale adoption.

4. Decision-Making Framework: Total Cost of Ownership (TCO)

The choice should not focus solely on upfront costs but on TCO, which includes:

Example: A 100 kW centrifugal pump using non-OEM impellers with 10% lower efficiency will consume an additional 10 kW of electricity. Over 8,000 operating hours per year, this equals 80,000 kWh in extra energy costs—far exceeding the upfront savings from non-OEM parts.

5. Conclusion

Non-OEM pump parts can be a cost-saving option in specific scenarios, but their adoption requires rigorous technical validation. Maintenance teams should:

1. Prioritize OEM parts during the warranty period to avoid losing manufacturer support.

2. For non-critical components or out-of-warranty equipment, select non-OEM parts from suppliers with proven quality and testing capabilities.

3. Evaluate TCO rather than upfront costs, considering energy consumption, maintenance frequency, and downtime risks.

Ultimately, the goal is to balance reliability and economy. For key pumps (e.g., those in continuous production lines or hazardous environments), the stability of OEM parts remains the most cost-effective choice in the long run. For non-critical equipment with low operating intensity, qualified non-OEM parts can be used with proper testing to reduce costs.