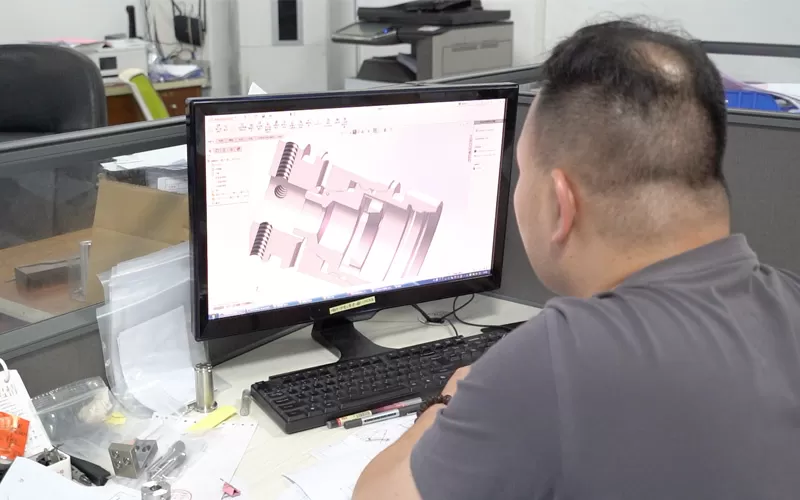

We have strict standard for CNC Milling

3-axis Milling

3-axis milling is the most commonly used CNC machining method, typically employed for producing simple parts, offering lower equipment costs.

4-axis Milling

4-axis milling is ideal for high-volume production of polyhedral parts, enabling simultaneous machining of three-dimensional surfaces from multiple angles.

5-axis Milling

5-axis machining enables the production of highly complex 3D geometries, offering both design flexibility and cost-effective manufacturing.

Horizontal CNC Milling

Horizontal CNC milling is a CNC milling method in which the cutting spindle is kept parallel to the table. The rigidity of the machine tool is superior.