Hydraulic Actuators in Machining: A Technical Overview

Selecting the right hydraulic actuator for machining applications becomes straightforward once system requirements are defined—but optimizing its performance within a machining setup is where true expertise comes into play. Interestingly, the mechanics of hydraulic actuators mirror biological systems: much like the human heart pumps blood to power muscles, a hydraulic system uses a pump to drive actuators, which act as the "muscles" of machining equipment. Yet, just as our bodies need to avoid strain, hydraulic actuators require careful cushioning to prevent wear—specifically, decelerating pistons before they strike cylinder end caps to protect critical components.

The "Circulatory System" of Hydraulic Machining

In machining, hydraulic systems operate with striking parallels to the human body. The hydraulic pump functions like the heart, generating pressure to circulate hydraulic fluid through hoses and pipes (analogous to blood vessels). Sensors and control units act as the "brain," regulating flow and pressure, while hydraulic actuators serve as the "muscles"—converting fluid energy into mechanical motion to drive tools, clamps, or workpiece positioning systems. Without these actuators, precision tasks like heavy-duty cutting, pressing, or clamping in machining would be nearly impossible.

What Are Hydraulic Actuators in Machining?

A hydraulic actuator is a mechanical device that converts hydraulic energy (from pressurized fluid) into linear or rotational motion—critical for powering machining tools. Unlike intelligent systems, it does not "calculate" force or speed; instead, it relies on servo-controlled valves (pressure, flow, and direction control valves) to regulate the hydraulic energy it receives. In machining, this means actuators can deliver precise force for clamping workpieces, steady torque for rotating tools, or controlled linear motion for feeding cutting tools into materials—all without requiring manual adjustment.

Types of Hydraulic Actuators for Machining

Hydraulic actuators in machining are categorized by their motion: linear (for straight-line movement) and rotary (for rotational movement). Each serves distinct machining needs, with trade-offs in force, precision, and maintenance.

Linear Hydraulic Actuators

Linear actuators (hydraulic cylinders) produce straight-line motion—ideal for machining tasks like pressing, stamping, or feeding tools into workpieces (e.g., in punch presses or milling machines). Their key advantage is a high force-to-weight ratio, making them indispensable for heavy-duty machining: they can deliver immense clamping force to secure large workpieces or apply pressure for operations like forging.

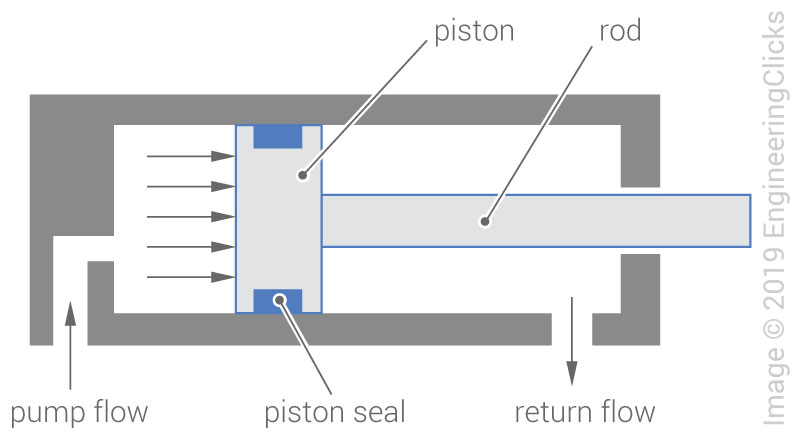

Linear actuators are either single-acting or double-acting:

A critical detail for machining: due to the piston rod occupying space on one side of the cylinder, linear actuators often have different forward and backward speeds. This asymmetry is managed via flow control valves to ensure consistent tool feeding rates—vital for maintaining cut precision.

Single-acting cylinders use hydraulic pressure to extend (e.g., pushing a tool into a workpiece) and a spring to retract—common in lightweight clamping systems.

Double-acting cylinders have ports at both ends, allowing fluid to drive motion in both directions. This makes them ideal for repetitive tasks like feeding a cutting tool forward and retracting it after a cut, or adjusting workpiece position in CNC machining centers.

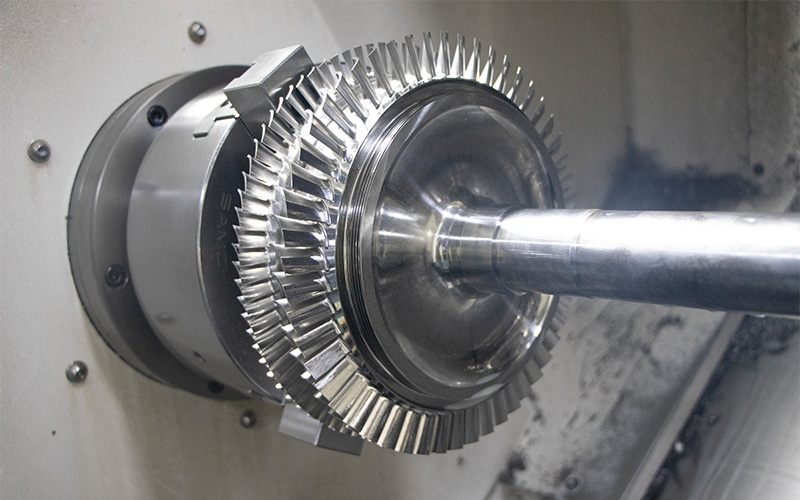

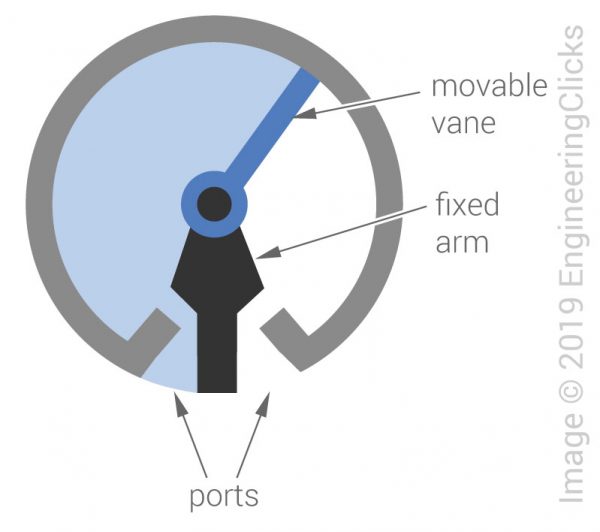

Rotary Hydraulic Actuators

Rotary actuators convert hydraulic energy into torque and rotational motion, used in machining for tasks like spinning workpieces (e.g., in lathes) or rotating cutting tools. However, they face challenges: sliding seals in rotary designs are prone to leakage, which can disrupt pressure and reduce precision. For this reason, many machining systems use a workaround: linear actuators drive a rack-and-pinion mechanism to convert linear motion into rotation. This hybrid approach combines the reliability of linear actuators with the rotational motion needed for tasks like indexing workpieces or adjusting tool angles.

Selecting the Right Hydraulic Actuator for Machining

Choosing an actuator depends on the machining task’s specific demands—from clamping force to tool feed speed. Key considerations include:

Force Requirements

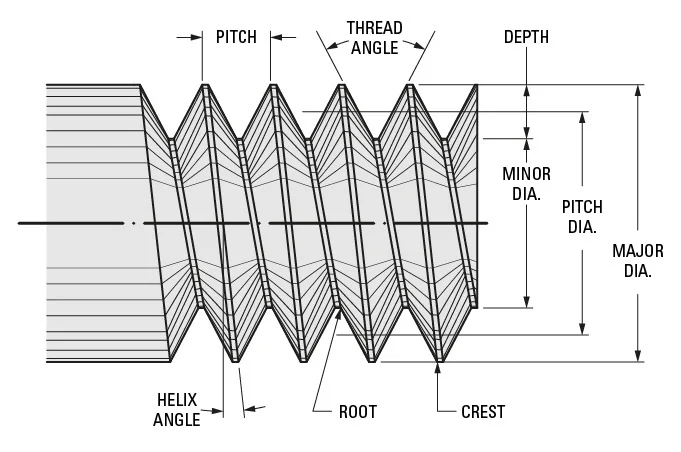

Machining tasks like heavy metal stamping or workpiece clamping demand high force, calculated as:

Force = System Pressure × Actuator Piston Area

Since a hydraulic system’s maximum pressure is limited by component durability (e.g., hose and valve ratings), the piston area becomes critical. For example, a punch press requiring 50,000 N of force at 20 MPa (200 bar) would need a piston area of 0.0025 m² (or a bore diameter of ~56 mm).

Motion Precision

For tasks like tool feeding or workpiece positioning, speed consistency is key. Linear actuators with a single piston rod have unequal effective areas on either side of the piston, leading to different extension and retraction speeds. In precision machining (e.g., CNC milling), this is mitigated by using double-rod cylinders—where equal piston areas on both sides ensure uniform speed in both directions.

Buckling Resistance

In machining, actuators often operate under eccentric loads (e.g., when a clamp presses unevenly on a workpiece). This can cause piston rods to buckle. To prevent failure, piston rod diameter is typically sized to 50% of the cylinder bore diameter—a ratio that balances strength and weight, ensuring stability even under off-center forces.

Cushioning for Longevity

In high-speed machining, actuators must stop abruptly without damaging components. Cushioning systems address this by trapping fluid near the end of the piston stroke and releasing it through a throttle valve, creating controlled deceleration. This prevents the piston from slamming into the cylinder end cap—critical for preserving seals and extending actuator life, especially in high-cycle operations like automated assembly-line machining.

Why Hydraulic Actuators Matter in Modern Machining

Hydraulic actuators are the backbone of precision and power in machining. Their ability to deliver high force with controlled motion makes them essential for tasks ranging from heavy forging to delicate workpiece positioning. By understanding their types, selection criteria, and maintenance needs, machinists can optimize performance, reduce downtime, and ensure consistent quality—whether shaping metal in a factory or fine-tuning components in a CNC workshop. In the world of machining, where precision and reliability define success, hydraulic actuators are not just components—they are the driving force behind efficiency.

Conclusion

At HL Parts, we specialize in providing top-quality aluminum anodizing services that are designed to meet your specific needs and help you stay ahead in a competitive market. Upload your file and let’s get started!