Surface Roughness Charts & Essential Insights

No engineering component’s lifespan can be accurately predicted without accounting for surface roughness. To the naked eye, a surface might appear perfectly smooth, but at a microscopic level, absolute flatness is unattainable in manufacturing. This is where profilometers—tools designed to measure surface irregularities—become critical. Surface roughness charts translate these microscopic deviations into quantifiable data, playing a key role in assessing friction between contacting surfaces, among other critical factors.

A surface roughness chart quantifies how much a surface deviates from ideal flatness. Since true microscopic flatness is impossible to achieve, every manufactured surface has a measurable roughness value, determined using profilometers. The type of profilometer and classification applied depend on the scale of these deviations and the specific roughness parameters being analyzed.

Practical Engineering Significance of Surface Roughness

Understanding surface roughness is far more than a technical detail—it drives real-world engineering decisions. Surface roughness charts empower designers to forecast critical performance metrics:

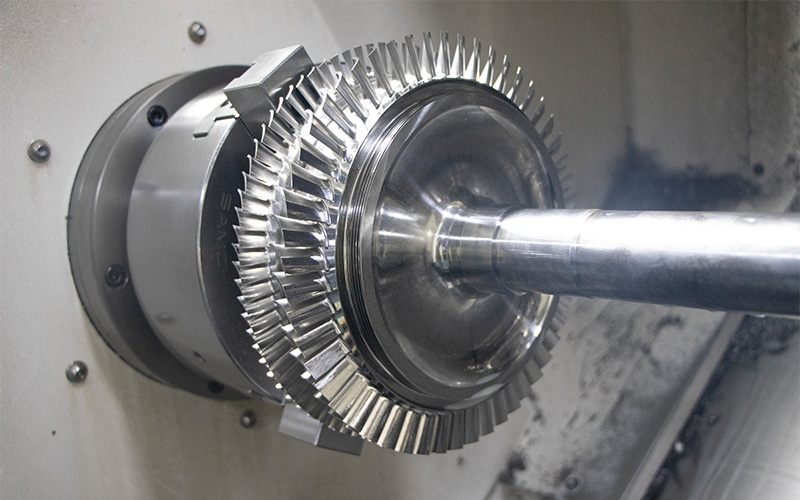

Friction levels between mating surfaces (e.g., in gear systems or sliding mechanisms).

Efficiency of braking systems, where surface texture directly impacts stopping power.

Precision of machining processes, helping validate whether tools or methods meet tolerance requirements.

Effectiveness of surface finishes (e.g., plating or polishing) and their suitability for roles like retaining lubrication.

Vibration patterns in mechanical systems, as rough surfaces can amplify oscillations.

Longevity of components, as excessive roughness accelerates wear and fatigue.

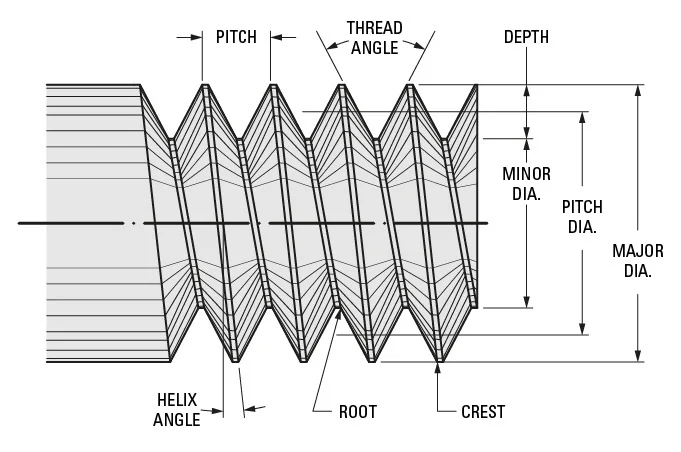

Measurement Standards and Physical Parameters

To standardize surface roughness measurements, the ISO 4287:2000 standard (an update to the 1997 version) defines key parameters. These include:

Rv (Maximum Valley Depth): The deepest depression in the measured surface profile.

Rp (Maximum Peak Height): The highest elevation in the measured profile.

Rsk (Skewness): A measure of asymmetry in the profile—whether peaks or valleys dominate.

Rku (Kurtosis): Describes how sharp or rounded peaks/valleys are (e.g., sharp peaks vs. flat, plateau-like surfaces).

Rtm (Total Peak-to-Valley Distance): The vertical gap between the highest peak and lowest valley over the measured length.

These parameters feed into two primary metrics used in charts:

Ra (Arithmetic Average Roughness): The average of all deviations from the mean line over the measured profile— the most widely used metric.

Rt (Total Roughness): The maximum peak-to-valley height in the profile, capturing extreme deviations.

Classification Scales

Surface roughness values (typically in micrometers, μm) align with standardized classifications:

ISO N Numbers: Range from N1 (smoothest) to N12 (roughest), with each number corresponding to specific Ra and Rt ranges. For example, N9 correlates to a Ra of 6.3 μm.

Grit Numbers: Used for abrasive finishing (e.g., sandpaper), where higher grit numbers indicate finer finishes. A Grit 500 finish, for instance, achieves an Ra of ~0.1 μm—equivalent to ISO N3.

Surface Roughness Charts

ISO Classification Chart

ISO Number | Ra (μm) | Rt (μm) |

N12 | 50 | 200 |

N11 | 25 | 100 |

N10 | 12.5 | 50 |

N9 | 6.3 | 25 |

N8 | 3.2 | 13 |

N7 | 1.6 | 8 |

N6 | 0.8 | 4 |

N5 | 0.4 | 2 |

N4 | 0.2 | 1.2 |

N3 | 0.1 | 0.8 |

N2 | 0.05 | 0.5 |

N1 | 0.025 | 0.3 |

ISO Classification Chart

Grit Number | Ra (μm) | Rt (μm) |

60 | 6.3 | 25 |

80 | 1.8 | 9 |

120 | 1.32 | 6.6 |

150 | 1.06 | 5.3 |

180 | 0.76 | 3.8 |

220 | 0.48 | 2.4 |

240 | 0.38 | 1.9 |

320 | 0.30 | 1.5 |

400 | 0.23 | 1.3 |

500 | 0.1 | 0.8 |

Real Examples – manufacturing process surface roughness chart

Here is how various manufacturing, cutting, finishing, and forming processes compare, and what range of Ra values is to be expected with each one of them.

Process | Range of Ra (μm) |

Sand Casting, Hot Rolling, Flame Cutting | 25 – 12.5 |

Forging | 12.5 – 3.2 |

Sawing, Planning, Shaping, Perm Mold Casting, Investment Casting, Chemical Milling, EDM | 25 – 1.6 |

Milling, Broaching, Reaming, Die Casting, Extruding, Cold Rolling, Drawing, Electron Beam Curring, Laser Cutting | 6.3 – 0.8 |

Boring, Turning | 6.3 – 0.4 |

Barrel Finishing, Electrolytic Grinding, Roller Burnishing | 0.8 – 0.2 |

Grinding, Polishing, Honing, Electro-polishing | 1.6 – 0.1 |

Lapping | 0.4 – 0.05 |

Superfinishing | 0.2 – 0.025 |

Conclusion

In summary, surface roughness charts bridge microscopic reality with macroscopic performance. By translating irregularities into measurable data, they enable engineers to design more reliable, efficient, and long-lasting components, proving that even the smallest surface details can have the biggest impact on engineering success.