A Comprehensive Guide of CNC Machined Plastics

Introduction

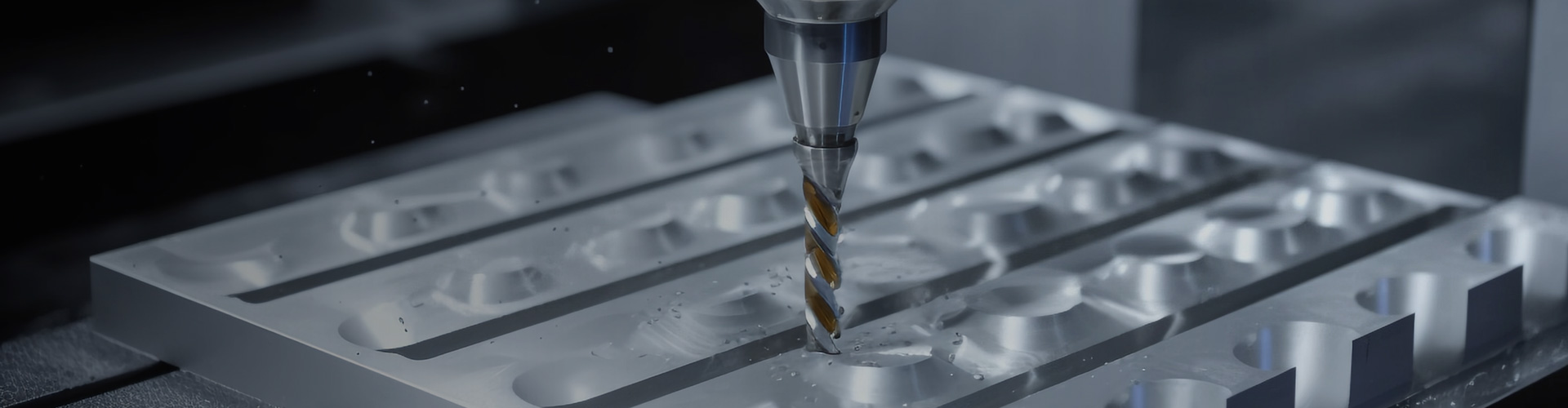

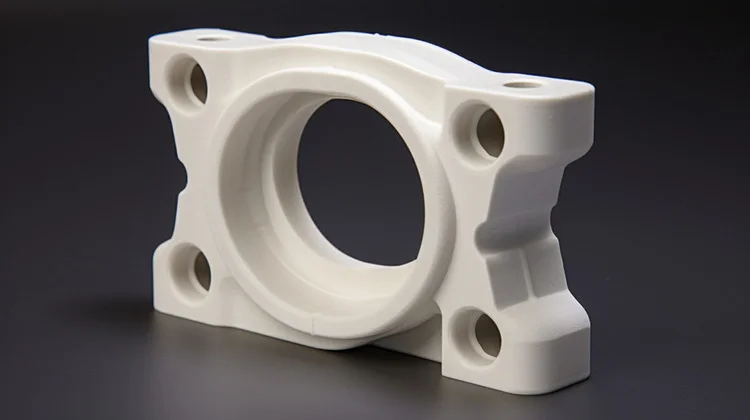

CNC (Computer Numerical Control) machining stands as a paragon of precision and efficiency in the manufacturing realm. It's a process that has the remarkable ability to transform a wide array of materials, including ceramics, wood, and composites, into high-quality parts. When the need arises for a plastic part, and CNC machining is the chosen route, the crucial first step is selecting the appropriate type of plastic. With an extensive range of machinable plastics available, the decision-making process can seem daunting. But fret not, as this in-depth article is here to illuminate the path, providing you with all the necessary insights to make an informed choice.

Common Plastic Materials in CNC Machining

Not every plastic is cut out for machining. The machinability of a plastic hinges on key mechanical properties such as impact strength, wear resistance, and dimensional stability. These characteristics can also vary based on how the material is treated. For example, many high-temperature thermoplastics like PEEK and PPS undergo annealing prior to machining. This annealing process serves to reduce internal stress and enhance stability, making them more suitable for the precise demands of CNC machining.

Thermoplastic materials, in general, tend to yield favorable results when processed via CNC machining. Now, let's take a closer look at some of the most commonly utilized plastics in this context. For an even more extensive selection of plastics, HL Parts's Plastic CNC Machining Services offer a wealth of additional details.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a true workhorse in the world of plastics. It's a versatile, general-purpose material that strikes an excellent balance between toughness, impact resistance, and machinability, all at an affordable price point. Whether it's injection molding, CNC machining, or 3D printing, ABS can be easily processed. It also boasts a relatively broad forming temperature range, adding to its versatility. Additionally, it lends itself well to various finishing techniques, such as painting, coating, or plating, allowing for customization to suit different aesthetic and functional requirements.

However, ABS does have its limitations. It lacks good abrasion resistance and offers only limited chemical resistance when exposed to strong acids, alkalis, and solvents. Prolonged exposure to UV light or harsh outdoor conditions can lead to aging, discoloration, and cracking. Moreover, in high-temperature environments, its strength and dimensional stability may deteriorate.

Common applications of ABS span a wide range of industries. It's frequently used for pre-injection molding prototypes, household appliances, electronic enclosures, automotive dashboards, and even those beloved Lego bricks.

POM / Delrin/ Acetal (Polyoxymethylene)

Delrin, the trade name by DuPont for homopolymer acetal, is highly regarded in the manufacturing industry. It exhibits high tensile strength and stiffness, enabling it to maintain its shape and strength even under long-term or repetitive loads. With its exceptional dimensional stability and machinability, Acetal/POM is a top pick for CNC-machined plastic parts that demand precision and tight tolerances. It also offers excellent resistance to a variety of chemicals, including oils, fuels, weak acids, and bases. The smooth surface and low friction coefficient of POM make it particularly well-suited for parts that involve sliding or rolling applications.

While POM can operate within a temperature range of -40°C to 120°C, higher temperatures can cause it to degrade or decompose. Its resistance to UV light is poor, and as a flammable material, appropriate fire safety precautions must be taken during its use.

Common applications of POM include mechanical transmission parts like gears, bearings, pulleys, and cams. It's also widely employed in the automotive, consumer electronics, and medical device industries.

Acrylic/PMMA (Polymethyl Methacrylate)

Acrylic, or PMMA, is a transparent thermoplastic that stands out for its exceptional optical properties. With a light transmission rate of up to 92%, it surpasses glass in transparency and is also lighter in weight. These qualities make it an ideal lightweight alternative to glass, especially for applications such as light pipes. It also offers good weather resistance and UV stability, performing reliably in outdoor environments.

However, when compared to engineering plastics like PC, PMMA has lower impact strength and is more prone to cracking or shattering. Its surface is relatively soft, making it susceptible to scratches. One notable aspect is that machined surfaces on acrylic lose their transparency and take on a frosted, translucent appearance. If transparency is required on a machined surface, additional post-processing steps like polishing can be employed.

Acrylic is commonly used in applications such as light covers, display stands, optical lenses, decorative panels, screen protectors, and medical shields.

Nylon/PA (Polyamides)

Nylon comes in various forms, with Nylon 6/6 and glass-filled nylon being the most commonly used at HL Parts. Both variants are excellent materials for CNC machining and retain the key benefits of standard nylon, such as high strength, toughness, low friction, exceptional wear resistance, and good chemical resistance.

Nylon 6/6 has a more ordered molecular structure and higher crystallinity compared to Nylon 6. This results in enhanced strength, rigidity, and a higher heat deflection temperature. Although its moisture absorption is slightly lower than that of Nylon 6, it can still impact dimensional stability in humid environments.

Glass-filled nylon incorporates glass fibers, which significantly boost its strength and rigidity, making it suitable for high-load applications. It also features reduced thermal expansion, improved dimensional stability, and superior heat resistance, making it a great choice for demanding high-temperature environments. However, machining glass-filled nylon is more challenging and can cause increased tool wear during CNC processing. Both types of nylon resist oil, fuel, and many chemical solvents but perform poorly in strong acid environments.

Common applications of nylon include gears, bushings, fasteners, circuit board mounting hardware, electrical insulation, automobile engine compartment components, and industrial conveyor belt guides.

PC (Polycarbonate)

Similar to PMMA, PC is a transparent thermoplastic. However, it offers a significant advantage in terms of impact resistance, being 10 - 20 times more impact resistant than PMMA and one of the toughest engineering plastics available. PC can be easily processed through CNC machining, injection molding, and extrusion, and is suitable for operations like drilling, cutting, and polishing. It maintains dimensional stability and performs well across a wide temperature range (-40°C to 120°C). Its natural milky-blue tint and glossy finish can be dyed black for applications where opacity is desired, combining functionality with aesthetics.

Pure polycarbonate has poor wear resistance and is prone to scratching. To address this, anti-scratch coatings and vapor polishing can be added as post-processing steps to improve wear resistance and optical clarity. It also has limited weather resistance and tends to yellow when exposed to UV light for extended periods. Additionally, its cost is higher than that of general plastics like ABS, which may restrict its use in large-scale applications.

PC is commonly used in safety equipment such as helmets and goggles, optical components like lenses and LED covers, electronic housings, automotive parts like light covers, and construction materials such as transparent roofing and sound barriers.

PEEK (Polyether Ether Ketone)

PEEK is a high-performance thermoplastic that truly stands out. It has the remarkable ability to withstand extremely high temperatures, up to around 250°C continuously and even 300°C for short periods, far surpassing the thermal limits of most common plastics. It offers exceptional mechanical strength, rigidity, toughness, wear resistance, and chemical corrosion resistance. Its low moisture absorption ensures dimensional stability, and it also exhibits good biocompatibility.

Compared to other high-performance plastics, PEEK has a higher density. Despite its strong chemical resistance, prolonged exposure to UV light and oxygen can cause degradation. PEEK is also more expensive than most CNC plastics, due to both the high cost of raw materials and the complexity of the machining process.

PEEK is commonly used in aerospace applications for engine components and seals, in the automotive industry for high-performance parts, in the medical field for implants and instruments, in the chemical industry for valves and pumps, and in electronics for cable insulation and connectors.

PVC (Polyvinyl Chloride)

PVC is an economical, easy-to-process, and practical plastic. It offers strong resistance to acids, alkalis, salts, and organic solvents and is an excellent electrical insulator. Thanks to its high chlorine content, PVC has impressive flame-retardant properties, making it a widely used material across numerous industries.

However, PVC has poor heat stability and can degrade or become brittle when exposed to high temperatures for extended periods. During processing, it may release harmful chlorine gas, necessitating appropriate safety measures.

Common applications of PVC include drainage pipes, electrical cable insulation, infusion tubes, pharmaceutical packaging, consumer goods packaging, billboards and signs, as well as flooring materials, window frames, and door frames in the building materials sector.

HDPE (High-Density Polyethylene)

HDPE, or High-Density Polyethylene, despite its name, is less dense than many engineering plastics like POM, PC, or PA. It offers excellent chemical resistance, electrical insulation, and retains good impact resistance and toughness even at low temperatures. HDPE has an extremely low moisture absorption rate and is considered food-safe.

The main drawbacks of HDPE include relatively low heat resistance and poor UV stability. Additionally, its mechanical properties are slightly lower than those of some engineering plastics, such as Nylon or POM, which may limit its performance in high-precision machining or under heavy load conditions.

Common applications of HDPE include water pipes, food packaging, storage containers, agricultural irrigation systems, and chemical storage tanks.

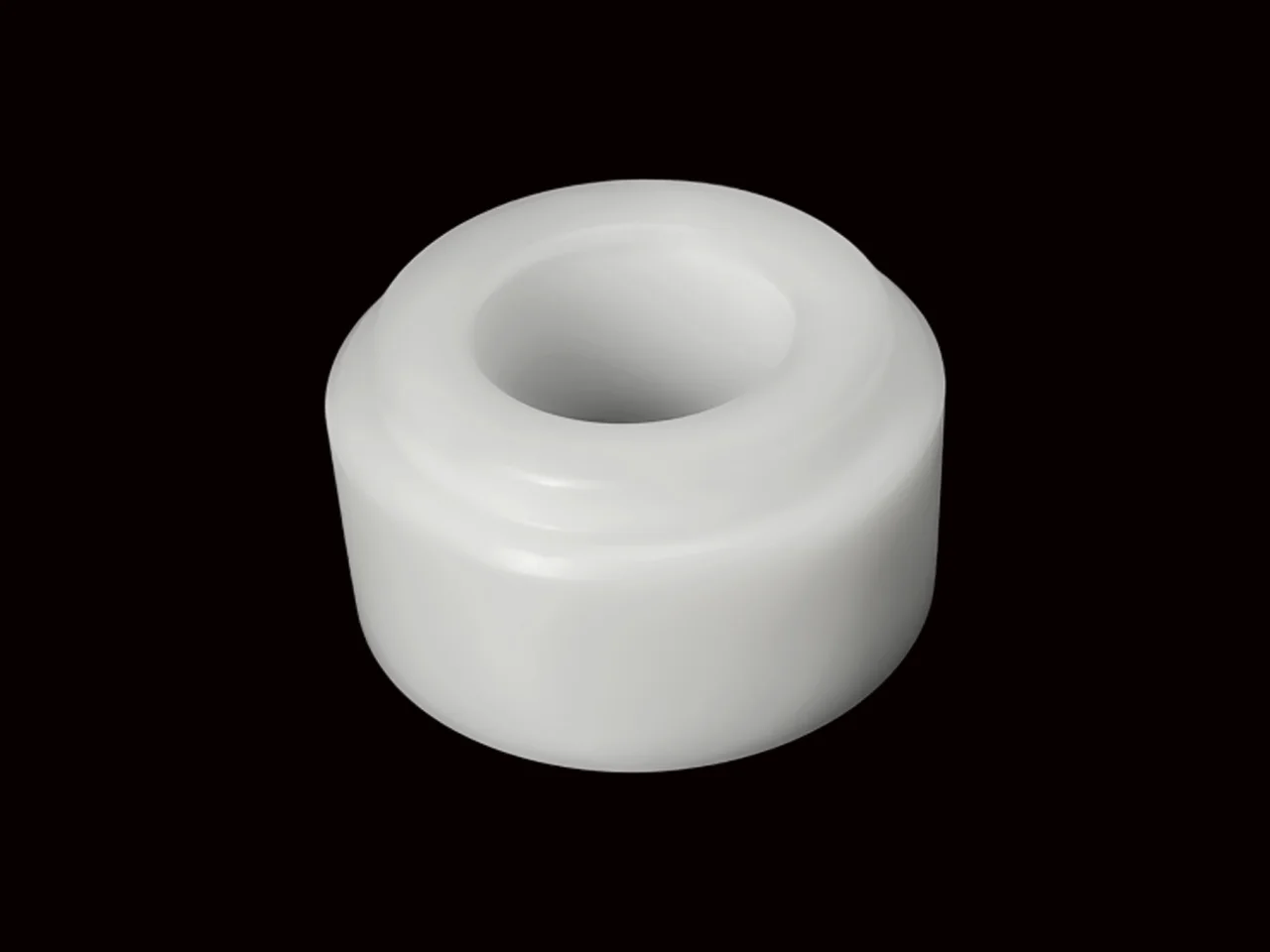

PTFE/Teflon (Polytetrafluoroethylene)

PTFE, commonly known by its brand name Teflon, is a white solid with an incredibly low friction coefficient, often regarded as the lowest among all solid materials. This unique property means that PTFE parts typically don't require lubricants. Its ultra-low surface energy makes it highly resistant to contamination and easy to clean. PTFE is also highly resistant to virtually all chemicals and has excellent heat resistance, capable of withstanding continuous exposure to temperatures up to 260°C (500°F). As a high-performance material, it serves as an excellent electrical insulator.

However, PTFE has lower mechanical strength compared to other engineering plastics like PEEK or POM and is prone to scratching or damage. It also has a high coefficient of thermal expansion, and during high-temperature processing, it can release harmful gases. These factors make precise machining of PTFE a challenging task.

Common applications of PTFE include seals, pipe linings, and valves in the chemical industry, equipment for food processing and pharmaceuticals, electrical cables, as well as seals and insulation materials in the automotive and aerospace industries, and sliding components such as rails and bearings.

Key Considerations When Choosing a Plastic

After exploring the common CNC plastics, it's evident that different plastics exhibit significant variations in their physical, mechanical, and chemical properties. These variations can have a profound impact on the outcome of your project. Here are the various factors you should take into account when it comes to plastic CNC machining.

Hardness and Strength

The hardness and strength of a specific plastic are crucial factors to consider to ensure it meets the requirements of its intended application. Plastics with high hardness generally offer better wear resistance, while those with high strength can withstand greater mechanical loads. Moreover, these properties influence how the material behaves during the machining process. High-hardness and high-strength plastics like POM, PEEK, and glass fiber-reinforced PA tend to produce short, regular chips and can achieve a high surface finish. However, they pose a greater challenge to cut, and tool wear occurs more rapidly.

On the other hand, softer or lower-strength plastics, such as PP, PVC, and PTFE, generate long, stringy chips during machining. These chips can easily wrap around the tool, leading to issues such as adhesion and gouging, which in turn affect the surface quality of the finished part.

Moisture Absorption and Chemical Reactivity

Unlike most metals, which do not absorb moisture from the air under normal circumstances, many plastics, including PA and PC, have the tendency to absorb moisture from the atmosphere or cooling fluids. This moisture absorption can cause dimensional expansion, thereby affecting the precision of CNC machining. Moisture can also soften plastics, reduce their toughness, or release internal stresses, all of which can impact the durability of the part. To mitigate these issues and prevent brittleness or machining defects, these plastics may need to be stored in air-conditioned environments, sealed bags, or dried thoroughly before machining.

In terms of chemical resistance, plastics generally show good resistance to most acids, alkalis, and salts. For instance, PTFE is almost inert to all chemicals, even in harsh conditions. However, some plastics, like ABS, are vulnerable to solvents such as acetone, which can dissolve the surface. PC, on the other hand, may crack when exposed to alcohols or alkaline solutions.

Appearance, Transparency, and Light Transmittance

For projects that demand specific aesthetic or optical properties, the light transmittance of the plastic material is a critical consideration. Applications such as optical components and display covers require materials with excellent transparency or specific optical characteristics. PMMA and PC are prime examples, as they offer high levels of transparency.

It's important to note that the machining process can have a significant impact on a plastic's optical performance. Even minor surface defects, scratches, or tool marks can reduce light transmittance and cause unwanted light scattering, compromising optical clarity. To maintain high transparency and surface quality, fine cutting, polishing, or chemical treatments are often necessary post-machining.

Thermal Expansion and Heat Deflection Temperature (HDT)

Plastics expand when exposed to heat, and this property is measured by the Coefficient of Thermal Expansion (CTE). Compared to metals, plastics typically have a much higher CTE (ranging from 50–250 × 10⁻⁶/°C, while metals like steel and aluminum have a CTE of 10–25 × 10⁻⁶/°C). The higher the CTE, the more significant the dimensional changes caused by heat during CNC machining, which can affect the precision of the final part. For high-precision applications, such as those in the aerospace and medical device industries, plastics with a high CTE, like POM and PTFE, may require design adjustments or compensations to maintain accuracy. Alternatively, low-expansion materials, such as PEEK or glass fiber-reinforced composites, can help minimize thermal distortion.

The Heat Deflection Temperature (HDT) measures a material's ability to resist deformation under load at elevated temperatures. Generally, a plastic's HDT is related to its stiffness. Materials with higher rigidity, such as glass-fiber-reinforced plastics and polyimides, tend to have higher HDT values, while more flexible polymers, like PE and PP, have lower ones. Plastics with a higher HDT can maintain dimensional stability under load at higher temperatures, ensuring that the part functions as intended. However, it's important to note that most plastics have an HDT significantly lower than that of metals. Their HDT typically ranges between 50°C and 250°C, and only a few high-performance engineering plastics, such as PEEK and PAI, can reach around 300°C.

Conclusion

CNC plastics offer a plethora of unique advantages over metals. They have a lower density, superior chemical resistance, excellent electrical insulation properties, and often come with cost-efficiency benefits. Additionally, they are compatible with a wide range of manufacturing processes, including CNC machining, 3D printing, and injection molding.

We hope this comprehensive guide has provided you with valuable insights that will empower you to make an informed decision when selecting CNC plastics for your projects. If you're still unsure whether CNC machining or 3D printing is the right choice for your needs, or if you're seeking expert guidance and high-quality CNC machining solutions, don't hesitate to contact HL Paarts today. Let's embark on your manufacturing journey together!

Key Takeaways

·Plastics are generally amenable to CNC machining, and ABS stands out as one of the most cost-effective options for prototyping, manufacturing, and general-purpose applications. Its affordability helps keep projects within budget without sacrificing essential performance characteristics.

·Acetal (Delrin) holds the title of the most popular CNC-machinable plastic. It's highly valued for its strength, stiffness, and dimensional stability, making it the go-to choice, especially for precision parts in industries such as automotive, electronics, and industrial machinery.

·For applications where robust chemical resistance is a must, plastics like PEEK, PVC, HDPE, and FEP shine. These materials can withstand exposure to a variety of chemicals, ensuring the longevity and functionality of parts in chemically challenging environments.

·Some heat-sensitive materials, including PEEK and PVC, require meticulous temperature control during CNC machining. Failure to do so can result in material degradation or the release of harmful gases, highlighting the importance of proper processing conditions.

·When transparency is a key requirement for an application, PC, Acrylic, or PET are worthy considerations. However, it's essential to be aware of their thermal limitations to ensure optimal performance.

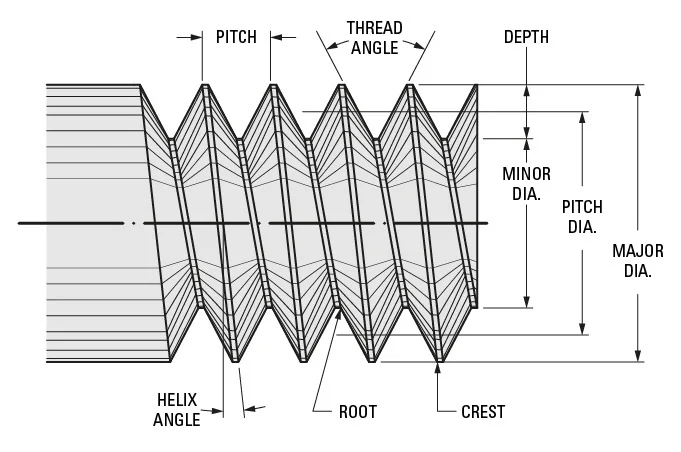

·A CNC mill is an excellent tool for machining plastics. However, special attention must be paid to mill speeds. Incorrect speeds can cause heat-sensitive materials to warp or melt, compromising the integrity of the part.