NC programming: types, definitions and techniques

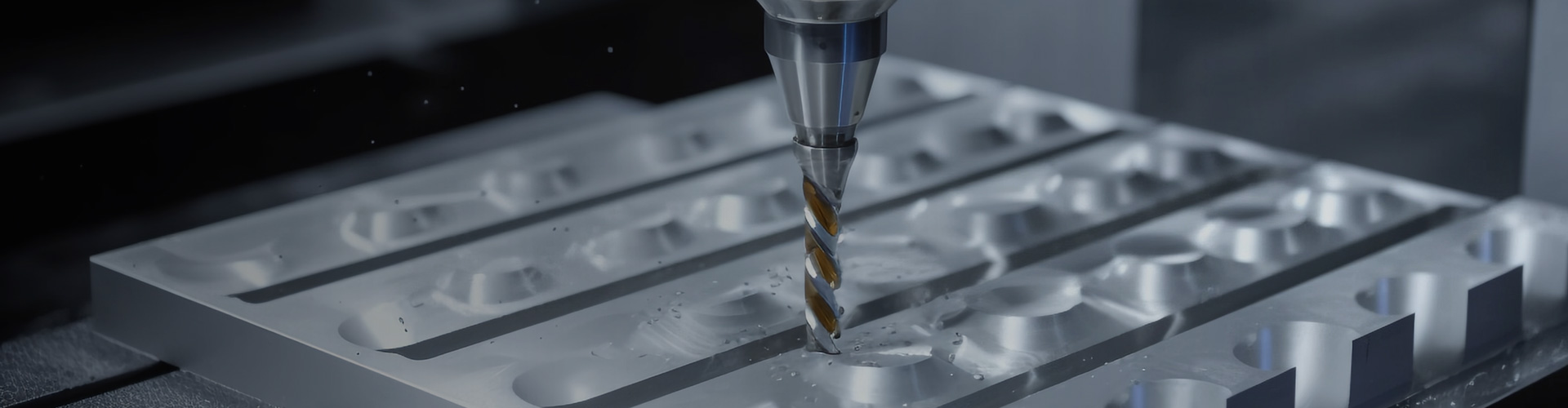

Computer Numerical Control (CNC) programming is the process of creating a set of instructions that dictate the movements and operations of a CNC machine. These instructions enable the machine to transform raw materials into finished products efficiently. CNC programming enhances productivity by enabling machines to perform repetitive tasks with precision, minimal waste, and reduced production time. Its benefits include lower operational costs, higher profitability, and business growth opportunities. CNC programming is used to control various machines, including routers, mills, lathes, mill-turn/turn-mill machines, multi-tasking centers, wire EDMs, and industrial robots. Instructions can be input either manually through a human interface or digitally using offline Computer-Aided Manufacturing (CAM) software.

Types of CNC Programming Methods

CNC programming can be executed through three primary techniques:

1. Manual CNC Programming

- The programmer manually writes the code, requiring in-depth knowledge of programming.

- While time-consuming and labor-intensive, manual programming remains essential for quick adjustments and code optimization.

- It serves as a foundational skill for CNC operators.

2. Conversational CNC Programming (Shop-Floor Programming)

- A user-friendly method where operators input commands directly into the CNC machine using graphical interfaces and menu-driven functions.

- Reduces errors caused by post-processing issues in CAM systems.

- Ideal for on-the-fly programming by skilled machinists.

3. CAM CNC Programming

- Uses Computer-Aided Manufacturing (CAM) software to generate CNC programs with advanced toolpath strategies.

- Features an intuitive graphical user interface (GUI) that simplifies program creation, eliminating the need for manual coding.

- Allows seamless transfer of programs to CNC machines, enhancing efficiency and automation.

Each method offers distinct advantages, catering to different production needs and operator expertise levels.

How to Choose the Right CNC Programming Method for Your Needs

CNC machines rely on precise programming to control tool movements and achieve high accuracy. Since different programming methods exist—each with unique benefits and limitations—selecting the right one depends on factors like complexity, operator skill, and production efficiency.

1. Manual CNC Programming

- Best for: Skilled programmers who need full control over machining operations.

- Requirements: In-depth knowledge of G-code and CNC machine functions.

Advantages:

✔ Maximizes machine efficiency and reduces cycle time.

✔ Offers complete flexibility in program development.

✔ Often produces more optimized code than CAM-generated programs.

Disadvantages:

✖ Time-consuming to write and verify code.

✖ Higher risk of human error.

✖ Requires experienced CNC programmers, who may be in short supply.

2. Conversational Programming (Shop-Floor Programming)

- Best for: Beginners and quick, simple part production.

- Requirements: Basic CNC knowledge; no G-code expertise needed.

Advantages:

✔ Easy to learn with a user-friendly interface.

✔ Faster setup and programming (simple parts can be programmed in under 30 minutes).

✔ Reduces errors and material waste.

✔ More affordable than CAM systems.

Disadvantages:

✖ Limited to simpler geometries and operations.

✖ Cannot handle complex toolpaths.

✖ Less flexibility compared to CAM or manual programming.

3. CAM System Programming

- Best for: Complex parts, high-volume production, and reducing reliance on skilled labor.

- Requirements: Basic CNC knowledge; CAM software proficiency.

Advantages:

✔ Automates G-code generation, reducing manual calculations.

✔ Minimizes programming-related machine crashes.

✔ Ideal for multi-machine environments.

Disadvantages:

✖ Still requires some programming knowledge.

✖ Operators have less direct control over machining strategies.

✖ May produce less optimized code than manual programming.

Key Considerations When Choosing a CNC Programming Method

- Complexity of Parts: Manual or CAM is better for intricate designs, while conversational suits simpler jobs.

- Operator Skill Level: Beginners benefit from conversational, while experts may prefer manual programming.

- Production Speed & Cost: CAM speeds up programming for large batches, whereas manual is best for precision optimization.

- Error Reduction: Conversational and CAM reduce mistakes, while manual requires careful verification.

By evaluating these factors, manufacturers can select the most efficient CNC programming method for their specific needs.

Essential CNC Programming Tips for Beginners

Starting with CNC programming can be challenging, but mastering these key principles will help build a strong foundation for success.

1. Master the Fundamentals

- A solid understanding of core CNC concepts is crucial for writing effective programs.

- Strengthen math skills (geometry, trigonometry) to improve manual and conversational programming accuracy.

- Regularly review G-code commands and machine operations to stay proficient.

2. Optimize Feed Rates for Efficiency

- Proper feed and speed settings significantly impact machining quality and tool life.

- CNC machines default to the last RPM setting if no speed command is given—always specify spindle speed.

- Adjust feed rates based on material, tool type, and desired finish for optimal performance.

- Experiment with different settings to find the best balance between speed and precision.

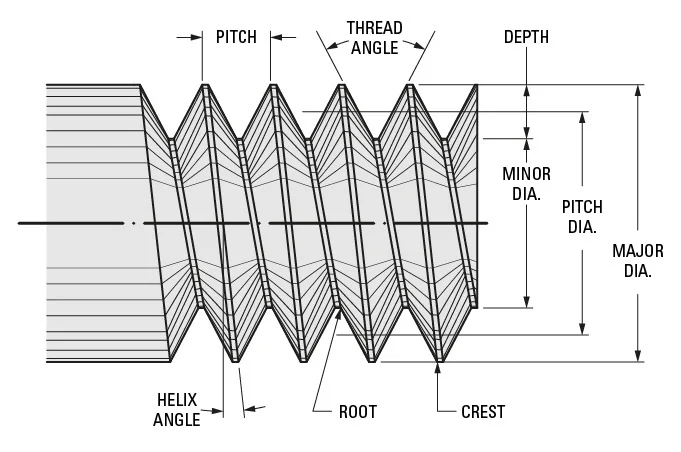

3. Understand CNC Compensation Types

Machining variations can affect part accuracy, so compensation adjustments are essential. Key types include:

- Cutter Radius Compensation (G41/G42) – Adjusts for tool diameter differences.

- Tool Length Compensation (G43/G44) – Accounts for varying tool lengths.

- Tool Wear Compensation – Corrects for gradual tool degradation.

- Fixture Offsets – Aligns workpiece positioning for consistent results.

Why It Matters:

- Even with perfect programming, factors like tool pressure can alter final dimensions.

- Manual corrections or automatic presetter tools help fine-tune accuracy during machining.

- Regular compensation adjustments enhance precision and reduce scrap parts.

Choose Your Best Manufacturing Partner

Depending on the specific demands of your design, you may have chosen one side in the titanium vs. steel debate. However, it's essential to strike a balance between the requirements of your project and the advantages and limitations of each metal before making a final decision. This process may seem trivial and can be complex. Don’t worry!HL Parts is here to guide you through it.

HL Parts provides custom manufacturing and die casting services. Regardless of your order size, we can provide high-quality components with precise tolerances and excellent surface finishes. Contact us for guidance and professional advice on your design, manufacturing, and material usage.

Final Advice for New CNC Programmers

✔ Start simple – Practice with basic projects before tackling complex parts.

✔ Test and verify – Always run simulations or dry runs to catch errors.

✔ Learn from mistakes – Adjust feeds, speeds, and compensations based on real-world results.

By focusing on these fundamentals, beginners can develop efficient, error-free CNC programming skills.