The Difference Between Titanium and Steel

When choosing a high-strength metal for specialized applications, titanium and steel frequently emerge as leading contenders. While both are renowned for their durability, they possess distinct characteristics that lend themselves to different use cases. So how do you determine which material best suits your needs? This guide examines the key attributes of both metals, offering a detailed comparison of their properties to help inform your decision. Read on for a comprehensive analysis.

What is the Titanium?

Titanium is a naturally occurring, nonmagnetic element with the chemical symbol Ti and atomic number 22 on the periodic table. It often exists in oxide forms, such as FeTiO3, and is found in various compounds and minerals. In the 1940s, William J. Kroll developed the Kroll process, which improved titanium extraction by reducing titanium tetrachloride with magnesium, making commercial production feasible.

Titanium is a silver-colored, lustrous transition metal with a high strength-to-weight ratio. It also offers excellent corrosion resistance and biocompatibility. Despite being a relatively new material compared to other metals, titanium has become essential in many applications, including aerospace, medical devices, automobile engines, marine equipment, industrial machinery, and jewelry, especially when cost is not a major concern.

While commercially pure (CP) titanium provides high corrosion resistance, its high melting point (1,668 ℃) makes it difficult to machine or process. Therefore, titanium alloys, often combined with other metals such as iron and aluminum, are more commonly used.

An Overview of Steel

This versatile material combines impressive density and strength with surprising workability. Through controlled heat treatment, steel can be precisely hardened and strengthened, though its inherent susceptibility to corrosion led to the development of specialized variants like stainless steel.

Modern steel classification systems consider multiple parameters including chemical makeup, crystalline structure, manufacturing methods, and application requirements. The material exists in numerous formulations - from basic carbon steels to sophisticated alloy steels, corrosion-resistant stainless varieties, and ultra-hard tool steels. Its cost-effectiveness and adaptable properties have made steel ubiquitous across industries, forming the backbone of global infrastructure, transportation systems, manufacturing equipment, and countless consumer goods.

The Differences Between Titanium and Steel

Comparative Analysis: Titanium vs. Steel

To facilitate an informed material selection, we examine the key characteristics distinguishing titanium from steel across multiple performance metrics.

Elemental Composition & Crystalline Structure

Titanium exists as both a pure element and in alloyed forms. Commercially pure titanium (CP Ti) contains minor impurities (0.013–0.5%) such as nitrogen, oxygen, and iron, while common alloys like Ti-6Al-4V incorporate aluminum and vanadium. Steel, by contrast, is fundamentally an iron-carbon alloy, with additional elements (e.g., manganese, chromium) introduced to tailor its properties.

Structurally, titanium adopts a hexagonal close-packed (HCP) arrangement, contributing to its low density and high strength-to-weight ratio, whereas steel typically forms a body-centered cubic (BCC) or face-centered cubic (FCC) lattice, influencing its mechanical behavior.

Weight

Titanium’s 43% lower density makes it significantly lighter than steel, a critical advantage in aerospace, motorsports, and biomedical implants where weight reduction is paramount. Steel, being denser, remains preferable in applications where mass is not a limiting factor, particularly given its cost efficiency.

Hardness & Wear Resistance

Steel generally surpasses titanium in hardness, with high-carbon and tool steels achieving Rockwell C (HRC) values exceeding 60, compared to 30–35 HRC for Ti-6Al-4V. Consequently, steel dominates cutting tools, bearings, and wear-intensive components, while titanium’s wear resistance is often enhanced through surface treatments rather than bulk properties.

Strength

Both materials exhibit high strength, but their performance varies by grade:

- Unalloyed titanium matches low-carbon steel in tensile strength (~240–550 MPa).

- High-strength steels (e.g., alloy steels) can exceed titanium’s strength but at a weight penalty.

- Titanium excels in fatigue resistance, making it ideal for cyclic loading applications (e.g., aircraft components).

Corrosion Resistance

Titanium’s self-repairing oxide layer grants it exceptional resistance to saltwater, acids, and industrial chemicals, outperforming even stainless steel. Steel requires protective coatings or alloying (e.g., chromium in stainless grades) to mitigate corrosion, adding cost and complexity.

Formability & Machinability

- Steel is more ductile and easier to machine, particularly low-carbon and free-machining alloys.

- Titanium’s low thermal conductivity and work-hardening tendency demand specialized tooling and techniques, increasing production costs.

Conductivity

Neither material is an efficient conductor:

- Electrical: Titanium (~3.1% of copper’s conductivity) is inferior to most steels.

- Thermal: Steel dissipates heat better, though both lag behind copper/aluminum.

Weldability

- Steel accommodates conventional welding methods (MIG/TIG) with minimal precautions.

- Titanium requires inert-gas shielding (GTAW) or vacuum environments (VEBW) to prevent contamination.

Cost Considerations

Titanium’s extraction complexity, energy-intensive processing, and machining challenges result in prices 5–10x higher than steel. Steel’s abundant raw materials and streamlined production ensure cost-effectiveness for high-volume applications.

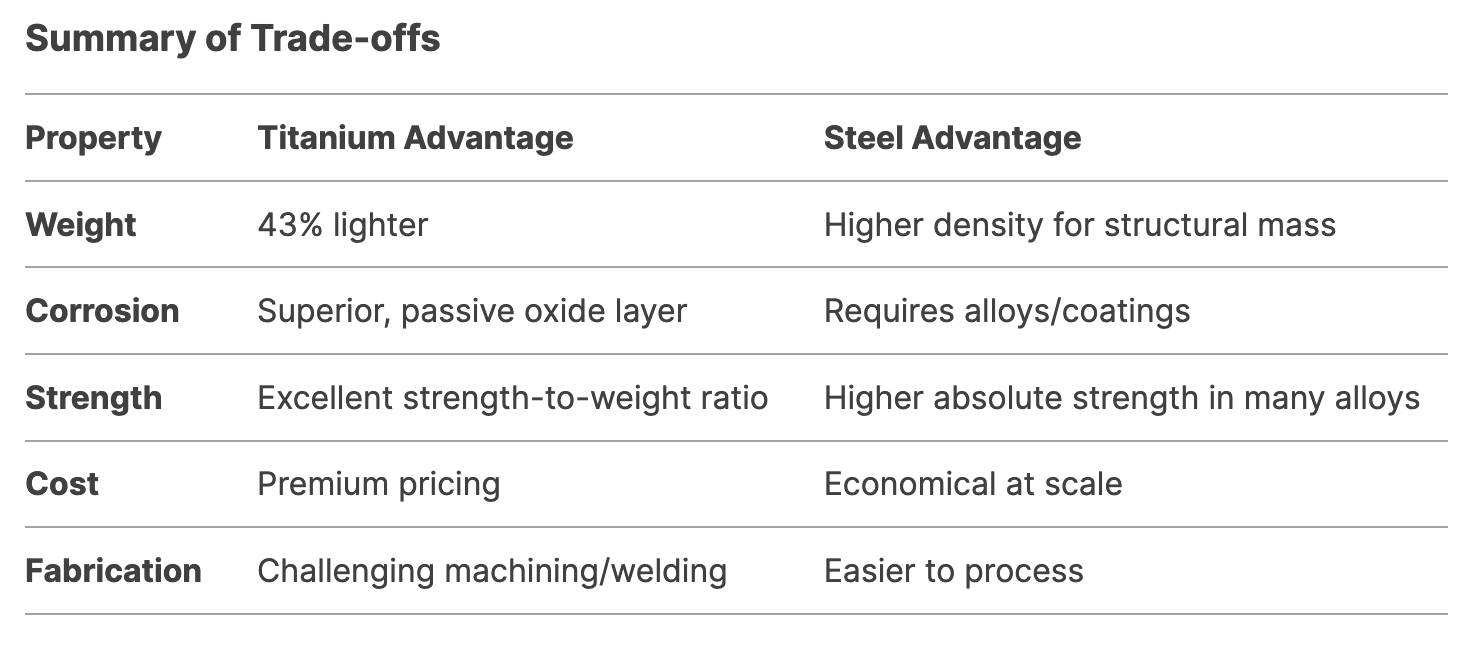

Summary of Trade-offs

Titanium vs. Steel:Which One to Choose?

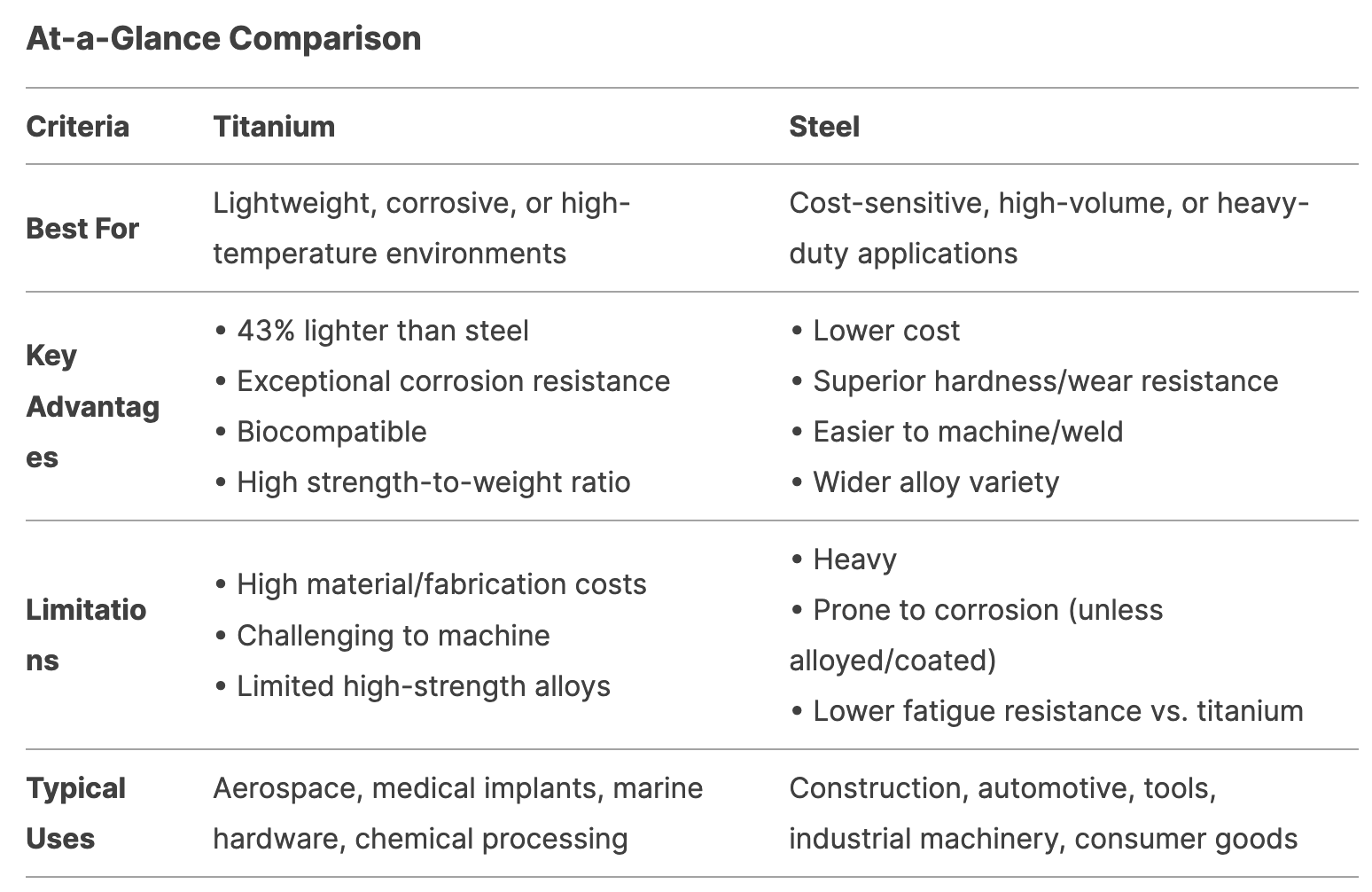

Material Selection Guide: Titanium vs. Steel

The comparative analysis reveals clear distinctions between these two metals. Below is a quick-reference summary of their key characteristics and optimal applications to aid your decision-making process.

When to Choose Steel

Steel emerges as the pragmatic choice when:

✓ Budget constraints exist – Significantly lower material and processing costs

✓ Manufacturability is critical – Easier to machine, weld, and form into complex shapes

✓ High-volume production is needed – Readily available in diverse alloy grades for tailored properties

✓ Absolute strength matters more than weight – Certain alloys outperform titanium in raw strength

When Titanium is Indispensable

The premium for titanium is justified when:

✓ Weight savings are paramount (e.g., aircraft components, performance vehicles)

✓ Corrosive or extreme environments are involved (e.g., offshore platforms, chemical reactors)

✓ Biocompatibility is required (e.g., surgical implants, dental devices)

✓ Fatigue resistance is critical (e.g., rotating parts subjected to cyclic stresses)

Decision Framework

To optimize your selection:

1. Prioritize requirements – Rank needs (cost, weight, corrosion resistance, etc.) in order of importance.

2. Evaluate trade-offs – For example: Can you accept higher weight for 80% cost reduction?

3. Consider lifecycle factors – Titanium’s durability may offset initial costs in long-term applications.

Final Note: While steel dominates in ubiquity and affordability, titanium’s unique properties make it irreplaceable for specialized applications. Your ideal material hinges on which characteristics deliver the most value for your specific use case.

Choose Your Best Partner

Depending on the specific demands of your design, you may have chosen one side in the titanium vs. steel debate. However, it's essential to strike a balance between the requirements of your project and the advantages and limitations of each metal before making a final decision. This process may seem trivial and can be complex. Don’t worry!HL Parts is here to guide you through it.

HL Parts provides custom manufacturing and fabrication services. Regardless of your order size, we can provide high-quality components with precise tolerances and excellent surface finishes. Contact us for guidance and professional advice on your design, manufacturing, and material usage.

Is Titanium Stronger than Steel

Strength Comparison: Titanium vs. Steel

While titanium's outstanding strength-to-weight ratio gives it a clear advantage in weight-sensitive applications, steel maintains dominance in absolute strength capabilities. The relative performance of these metals depends fundamentally on alloy selection and operational requirements.

Titanium alloys demonstrate remarkable efficiency in structural applications where mass reduction is critical. Certain high-performance titanium formulations can surpass the strength of standard steel grades while maintaining significant weight savings - a characteristic particularly valued in aerospace components and high-performance engineering.

Steel, through its extensive range of alloy compositions, offers unparalleled versatility in achieving extreme strength characteristics. Advanced high-strength steels consistently deliver superior load-bearing capacity, making them indispensable for heavy-duty structural applications where weight is secondary to ultimate durability.

The material selection between these metals ultimately hinges on whether the design priority favors mass efficiency (titanium) or absolute structural integrity (steel), with both materials offering exceptional performance within their respective optimal application spaces.