Q&A Series: Technical Insights into Pump Bearings

Bearings are critical rotating components in centrifugal pumps, responsible for supporting axial and radial loads while minimizing friction between the rotating shaft and stationary housing. Their performance directly affects the pump’s operating stability, energy efficiency, and service life. This Q&A series addresses key technical questions about pump bearings, providing a professional reference for maintenance and operation teams.

Q1: What Are Pump Bearings, and Why Are They Critical?

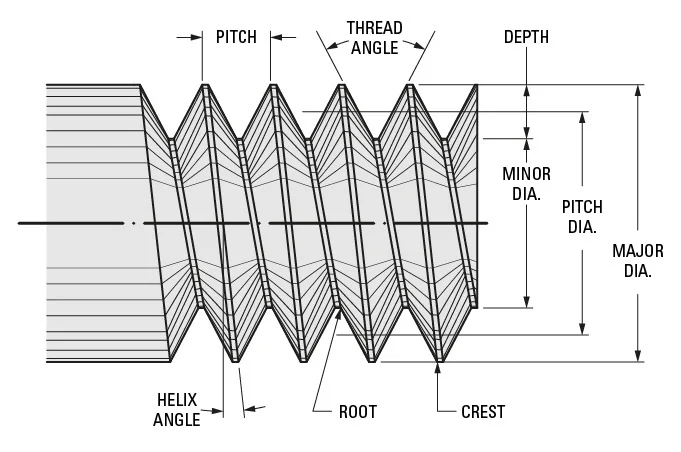

A: Pump bearings are precision mechanical components designed to support the rotating shaft, enabling smooth rotation under load. Their core structure typically includes:

·Rolling elements (balls, rollers, or shoes) that reduce friction through rolling motion.

·Inner and outer races (metal rings) that guide the rolling elements and distribute loads.

·Cage (retainer) that separates rolling elements to prevent collision and ensure uniform load distribution.

In centrifugal pumps, bearings perform two irreplaceable functions:

1. Load support: Bear radial loads (from impeller rotation) and axial loads (from fluid pressure differences) to prevent shaft deflection.

2. Friction reduction: Convert sliding friction between the shaft and housing into rolling friction, reducing energy loss (friction loss accounts for 3–5% of total pump power consumption).

A single bearing failure can cause shaft misalignment, impeller rubbing against the casing, or even complete pump shutdown. Statistics show that 40–50% of pump failures originate from bearing issues, making their maintenance a top priority.

Q2: What Mechanical Stresses Do Bearings Undergo During Pump Operation?

A: During operation, pump bearings face complex and continuous stresses, which are the main causes of wear and fatigue:

·Load stress:

·Radial load: Generated by the impeller’s imbalance (even a 0.1 mm runout can create 500–1,000 N radial force) and fluid turbulence.

·Axial load: Caused by pressure differences between the impeller inlet and outlet (can reach 20–30% of the radial load in single-suction pumps).

These loads cause contact stress between rolling elements and races (up to 1–3 GPa for ball bearings), leading to surface fatigue over time.

·Thermal stress:

Friction and heat transfer from the pump cavity raise bearing temperature (typically 40–60°C under normal operation). High temperatures (exceeding 80°C) accelerate lubricant degradation and material softening, reducing load-bearing capacity.

·Vibration and impact:

Impeller imbalance, cavitation, or pipeline pulsation causes shaft vibration (vibration velocity >2.8 mm/s is considered abnormal). Vibration leads to intermittent contact between rolling elements and races, generating impact stress that exacerbates wear.

·Lubrication challenges:

Lubricant film thickness (ideally 1–5 μm) is critical for separating metal surfaces. Under high speed or load, the film may thin or break, causing metal-to-metal contact and abrasive wear.

Q3: What Are the Common Types of Pump Bearings, and How to Choose Them?

A: Pump bearings are classified by structure and load-carrying capacity, with the following types commonly used in centrifugal pumps:

Selection Principles:

·Prioritize roller bearings for heavy radial loads; angular contact bearings for combined loads.

·Use pivot shoe bearings for large axial loads (e.g., multi-stage pumps with 3+ impellers).

·Choose sleeve bearings for high-speed applications (≥3,600 rpm) with clean, low-vibration conditions.

Q4: What Causes Bearing Failure, and How to Identify Early Signs?

A: Bearing failure is rarely sudden; it is usually caused by cumulative damage from improper operation or maintenance. Common causes and early warning signs include:

1. Contamination

·Causes: Ingress of dust, water, or slurry into the bearing cavity (e.g., damaged oil seals, loose bearing covers).

·Failure mode: Abrasive wear (scratches on races) or corrosion (rust spots on rolling elements).

·Early signs: Abnormal noise (grinding or clicking sounds), increased vibration (vibration velocity >4.5 mm/s).

2. Lubrication Failure

·Causes: Wrong lubricant type (e.g., using general grease in high-temperature pumps), insufficient/low grease (≤30% of cavity volume), or lubricant contamination (water content >5%).

·Failure mode: Dry friction (scoring on races), overheating (discolored metal surfaces), or lubricant caking.

·Early signs: Elevated temperature (≥80°C), grease leakage, or increased power consumption.

3. Installation/Alignment Errors

·Causes: Shaft misalignment (radial misalignment >0.1 mm/m), excessive interference fit (shaft over-tightening), or uneven bearing seating.

·Failure mode: Uneven load distribution (raceway wear on one side), cage deformation.

·Early signs: Asymmetric temperature rise (one end of the bearing hotter than the other), abnormal vibration in the axial direction.

4. Overload or Underload

·Causes: Excessive discharge pressure (overload) or low flow operation (underload, leading to rolling element skidding).

·Failure mode: Fatigue spalling (overload) or smearing (underload, caused by sliding friction).

·Early signs: Fluctuating temperature, abnormal noise under varying loads.

5. Environmental Factors

·Causes: High ambient temperature (≥40°C), corrosive gases (e.g., chlorine in water treatment), or electric current leakage (arcing damage to races).

·Failure mode: Material degradation, corrosion, or pitting.

·Early signs: Rust on outer races, pitted rolling elements.

Q5: How to Extend Bearing Service Life and Ensure Stable Performance?

A: Extending bearing life requires a combination of proper selection, installation, lubrication, and monitoring:

1. Scientific Lubrication

·Use lubricants matching operating conditions: Lithium-based grease (NLGI 2) for normal temperatures (–20–120°C); polyurea grease for high temperatures (>120°C); oil mist lubrication for high-speed pumps (>6,000 rpm).

·Control lubrication amount: Grease should fill 1/2–2/3 of the bearing cavity (overfilling causes overheating); oil level should reach 1/2 of the lowest rolling element.

·Adopt automatic lubricators (e.g., SlurryPro Automatic Lubricator): These devices inject a fixed amount of grease at set intervals (e.g., 1–3 g/h), avoiding human error in manual lubrication and ensuring a stable lubricant film.

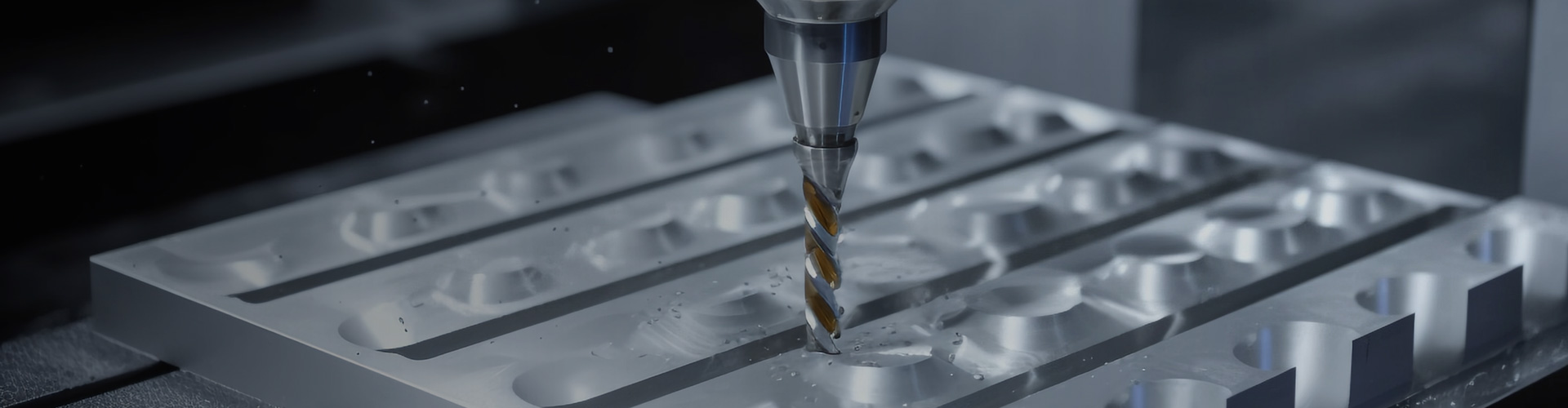

2. Precise Installation and Alignment

·Use hydraulic mounting tools to avoid hammering (which damages races); control interference fit (shaft tolerance H7/k6 for ball bearings).

·Ensure shaft alignment: Radial misalignment ≤0.1 mm/m, axial misalignment ≤0.05 mm/m (measured with laser alignment tools).

3. Real-Time Condition Monitoring

·Install temperature sensors (PT100) to track bearing temperature (alarm if >80°C).

·Use vibration analyzers to monitor vibration velocity (ISO 10816 standard: ≤2.8 mm/s for new pumps, ≤4.5 mm/s for used pumps).

·Regularly inspect lubricant: Check for water content (≤0.5%), particle contamination (ISO 4406: ≤18/15 for clean pumps).

4. Environmental Protection

·Seal the bearing cavity with labyrinth seals or V-ring oil seals to prevent dust/water ingress.

·For corrosive environments, use stainless steel bearings (e.g., 440C) or apply anti-corrosion coatings (e.g., zinc plating).

Conclusion

Pump bearings operate under complex stresses, and their failure can lead to costly downtime. By understanding their working principles, failure causes, and maintenance methods, teams can proactively extend service life—typically from 8,000–12,000 hours (standard conditions) to 15,000–20,000 hours with proper care. Remember: Bearing maintenance is not just about replacing worn parts but about systematic management of load, lubrication, and alignment.