The Guidance of the Pump Selection for Liquids and Slurries

Pump selection is a critical engineering decision that directly impacts system efficiency, operational reliability, and lifecycle costs. The core of this decision lies in matching the pump’s performance characteristics to the physical properties of the pumped medium. This guide systematically analyzes pump selection criteria for different media (liquids, slurries, viscous fluids, and corrosive substances) from a technical perspective, providing a professional basis for engineering applications.

1. Core Principles of Pump Selection

The primary criterion for pump selection is medium adaptability, which is determined by the following key attributes of the medium:

·Viscosity: Measured in centipoise (cP), it directly affects the pump’s hydraulic resistance and energy consumption.

·Solid content: Expressed as a volume percentage, it determines the pump’s anti-clogging and wear resistance requirements.

·Abrasiveness: Related to the hardness and shape of solid particles (e.g., sand, ore particles), it influences the selection of wear-resistant materials.

·Corrosivity: Determined by chemical composition (e.g., pH value, oxidizing properties), it dictates material compatibility (e.g., metal, non-metal).

Other auxiliary factors include conveying distance (head requirement), flow rate, and power source (electricity, pneumatic), but these are secondary to medium characteristics.

2. Classification of Media and Corresponding Pump Types

Media can be categorized into four main types based on their physical and chemical properties, each requiring specific pump designs:

2.1 Low-Viscosity, Solids-Free Liquids (e.g., water, light oils)

·Characteristics: Viscosity <100 cP, no solid particles, low abrasiveness.

·Recommended Pumps:

·Centrifugal pumps: Utilize centrifugal force generated by impeller rotation to achieve high flow rates (up to 10,000 m³/h) with simple structure and low maintenance. Suitable for water supply, irrigation, and general industrial transfer.

·Submersible pumps: Integrate pump and motor in a submersible design, eliminating suction lift limitations. Ideal for deep well pumping and tank emptying.

·Pneumatic pumps: Pneumatically driven, explosion-proof, suitable for hazardous areas where electric power is unavailable.

2.2 High-Viscosity Liquids (e.g., heavy oil, fruit pulp, asphalt)

·Characteristics: Viscosity 100–100,000 cP, no or few fine solids, high flow resistance.

·Recommended Pumps:

·Gear pumps/lobe pumps: Positive displacement designs with meshing gears/lobes to convey viscous fluids via volumetric displacement. Provide stable pressure and are suitable for oil transfer and food processing (e.g., chocolate conveying).

·Tube pumps/diaphragm pumps: Positive displacement with flexible tubes/diaphragms to avoid shear damage. Can run dry safely, making them suitable for intermittent operation scenarios (e.g., cosmetic paste transfer).

2.3 Slurries (e.g., mining tailings, sewage sludge, dredging mixtures)

·Characteristics: Mixtures of liquid and solids (solid content 5–60% by volume), with abrasive particles (particle size 0.1 mm–50 mm).

·Key Selection Factors:

·Solid concentration and particle size: Higher concentrations or larger particles require larger flow passages.

·Abrasiveness: Determines material selection (e.g., rubber liners for low abrasiveness, high-chrome alloys for high abrasiveness).

·Conveying distance/head: High head requires multi-stage designs or positive displacement pumps.

·Recommended Pumps:

·Centrifugal slurry pumps: Optimized impellers and volutes with wear-resistant liners (rubber, high-chrome cast iron). Provide high flow rates (up to 5,000 m³/h) and are suitable for continuous mining and mineral processing.

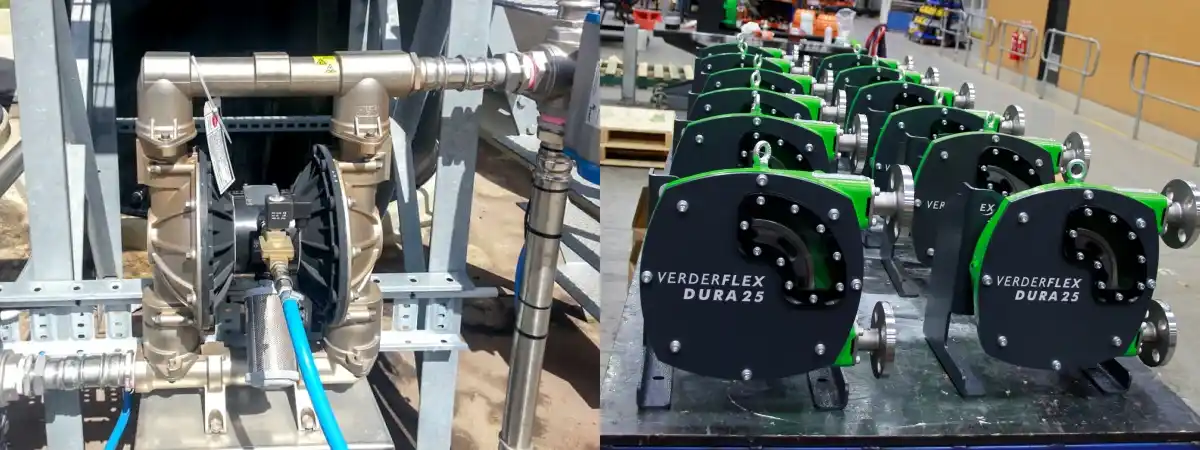

·Peristaltic hose pumps: Positive displacement with a flexible hose squeezed by rollers to convey slurry. No internal contact between slurry and pump components, eliminating wear. Ideal for high solids content (up to 60%) and abrasive slurries (e.g., concrete slurry).

·Submersible slurry pumps: Submerge directly in slurry (e.g., pits, tanks) to avoid suction line clogging. Suitable for dredging and sludge extraction.

2.4 Corrosive Media (e.g., acids, alkalis, chemical solutions)

·Characteristics: High chemical activity, may cause corrosion to metals or non-metals.

·Recommended Pumps:

·Chemical process pumps: Constructed with corrosion-resistant materials (e.g., stainless steel 316, PTFE, Hastelloy) based on medium chemistry. Sealing systems (mechanical seals, magnetic drives) prevent leakage, ensuring safe operation in chemical manufacturing and wastewater treatment.

3. Working Principle of Slurry Pumps

Slurry pumps rely on two core mechanisms to handle abrasive mixtures, with structural designs optimized for wear resistance:

·Centrifugal Slurry Pumps:

·Slurry enters the pump inlet and is accelerated by the rotating impeller (tip speed 10–30 m/s).

·Centrifugal force pushes the slurry toward the impeller periphery and into the volute, converting kinetic energy into pressure energy.

·The volute’s expanding flow path reduces velocity and increases pressure, conveying the slurry to the discharge pipeline.

·Wear-resistant liners and impellers (e.g., high-chrome cast iron with 27–30% Cr) minimize abrasion from solid impacts.

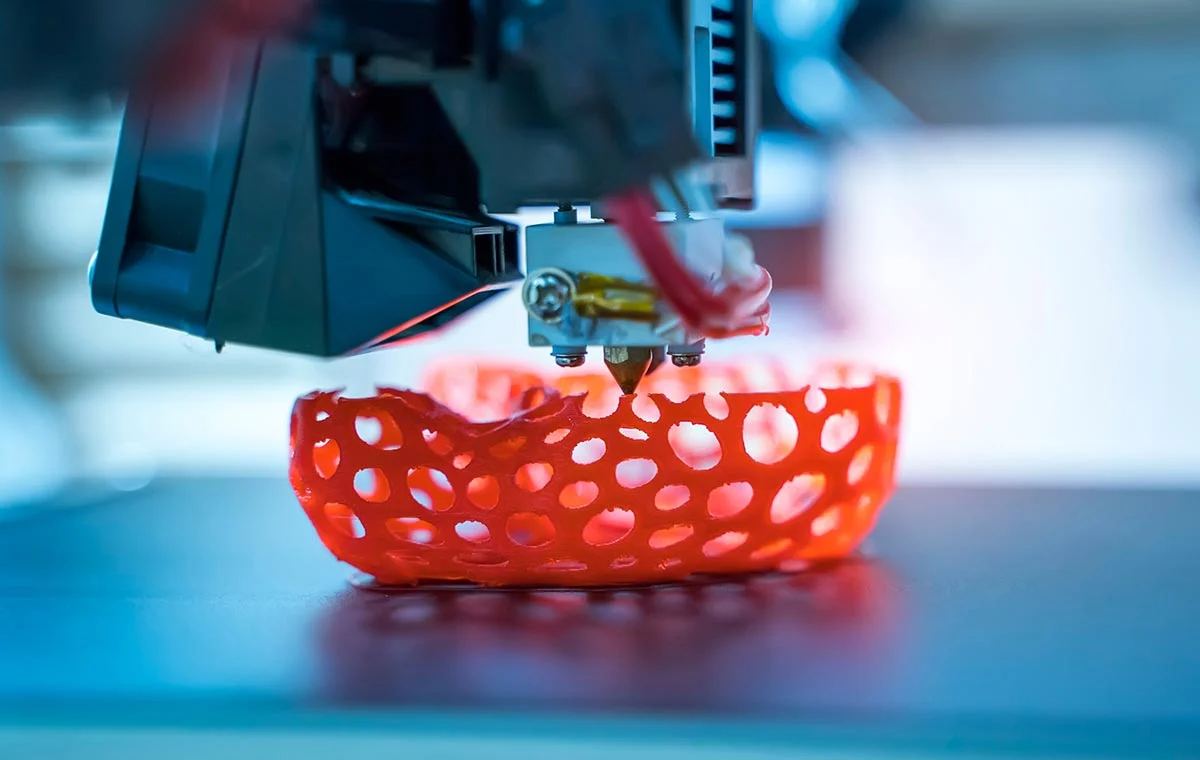

·Positive Displacement Slurry Pumps (e.g., peristaltic pumps):

·Slurry fills the flexible hose through the inlet as rollers rotate.

·Rollers squeeze the hose sequentially, pushing the slurry toward the outlet without internal friction.

·The hose rebounds after roller passage, creating a vacuum to draw in new slurry.

·The hose (made of natural rubber or polyurethane) is the only wearing part, reducing maintenance complexity.

4. Key Technical Considerations for Slurry Pump Selection

·Wear Resistance: Choose materials based on abrasive particle hardness (e.g., rubber for <5 Mohs, high-chrome alloy for >5 Mohs).

·Anti-Clogging: Ensure flow passages (inlet, impeller) are 1.5–2 times the maximum particle size to prevent blockages.

·Efficiency: Centrifugal slurry pumps have higher efficiency (60–80%) for large flow rates, while peristaltic pumps prioritize reliability over efficiency (40–60%).

·Maintenance: Peristaltic pumps have lower maintenance costs (only hose replacement), while centrifugal slurry pumps require periodic replacement of impellers and liners.

5. Conclusion

Pump selection must be based on a comprehensive analysis of medium properties (viscosity, solids content, abrasiveness, corrosivity) and operational requirements (flow rate, head, environment). For slurry applications, centrifugal slurry pumps excel in high-flow, continuous operations, while peristaltic pumps are preferred for high solids content and abrasive scenarios.

For complex applications (e.g., multi-phase media, extreme temperatures/pressures), professional technical evaluation is recommended to ensure optimal pump performance and lifecycle economy.