We have strict standard for CNC Turning

Swiss Turning Machining

Swiss turning is ideal for producing micro-precision parts and was originally developed for the manufacturing of small, high-precision components.

CNC Tool Lathe Machining

The CNC lathe offers fast tool change efficiency, high cutting speeds, and accommodates tools with compact sizes.

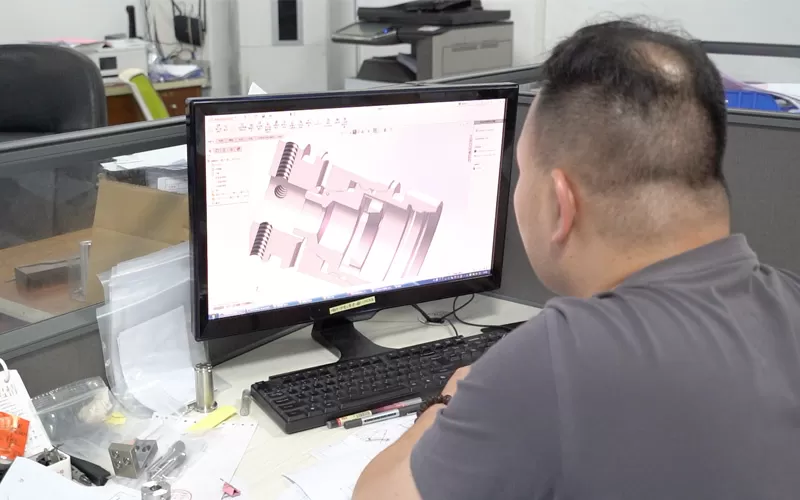

CNC Turning and Milling

CNC milling and turning is the only machining process that allows all cutting operations to be performed in a single setup.

4 axis CNC Turning

The 4-axis turret CNC turning tool minimizes overrun and supports milling of axial end faces and simple longitudinal geometries.